Gearbox fun

by Darren on Mar.05, 2013, under Build

OK, so last weekend I’d stripped the box and cleaned up the cases, but now it’s time to get serious. Firstly, the old ATB diff has been stripped of the crownwheel and bearings and put on eBay, so if you want one for an O2A box (fitted to a huge range of VAG group cars) then head over there to get yourself a bargain as they’re bloody expensive new!

Looking at the gear cluster, the ratios that are in there are the best choice from the standard sets available, and what is nice is that the final drive is a 4.61, meaning the car is geared much lower than standard overall – this looks to be an expensive item from the brief search I’ve made of online sellers of such stuff – around the £600 mark! I’d really like a close ratio setup as I had in the Skoda…. but the problem is that the only kits I can find are north of £1700, which is not an option at present, so it’ll have to stay standard.

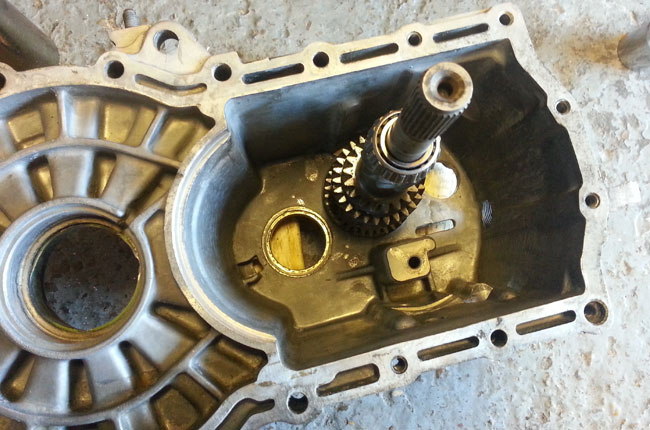

Now, time to rebuild the box. Looking at the old bearings, all of them look heavily worn, possibly because they weren’t set up correctly – they all look to have suffered a lot of heavy load, and while not as bad as the diff bearings, they were all in need of replacement. Setting up the box is a case of installing new bearings to a shaft, fitting the bearings into the case, and then measuring the end play of the shaft. This measurement is taken with the desired clearance (sometimes a negative clearance so the bearing will be under some pressure), and then the appropriate shim is purchased. The input shaft was first up, so old bearings pulled off:

And then new ones fitted, and the shaft popped in place:

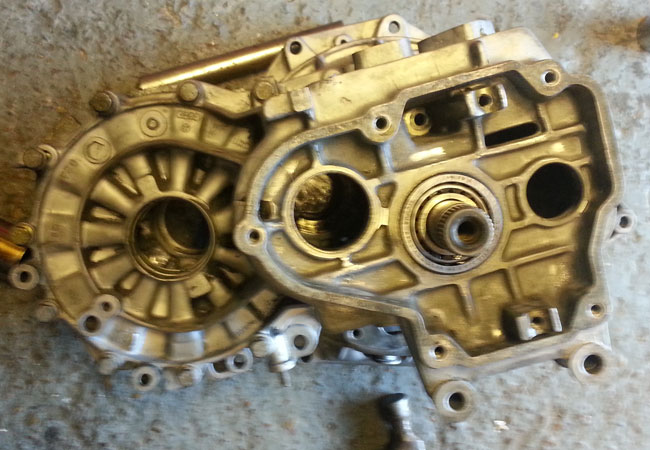

Next, the casing was fitted and bolted up to the correct spec, and the end play in the shaft measured.

Using the manual from VW I now know the correct shim I need for this shaft…. the problem I have is that I can’t go any further with the box now, for three reasons. Firstly, the next shaft needs a shim placed in one of the bearing housings to allow it to be removed (it’s in a blind hole, and without a shim behind there would be no way to remove it – it was a pig even with one in there). So I need to order that. But more importantly, I need to get a tool made up and a press to allow me to disassemble this shaft as it has three bearings, one of which is installed behind all the synchros. Once they’re all off I can set this bearing pair up and measure that.

The diff from Gripper…. has been ordered, but they are waiting for parts to arrive, so once they have them, I’ll be relieved of a load of money, and then I’ll have a diff that I can install and do the same procedure on as the other shafts. It’s just one of those jobs that will take a bit of messing about as there are several stages and special tools needed, alas! Still, it’s getting there… slowly.