Gearbox time!

by Darren on Sep.18, 2011, under Build

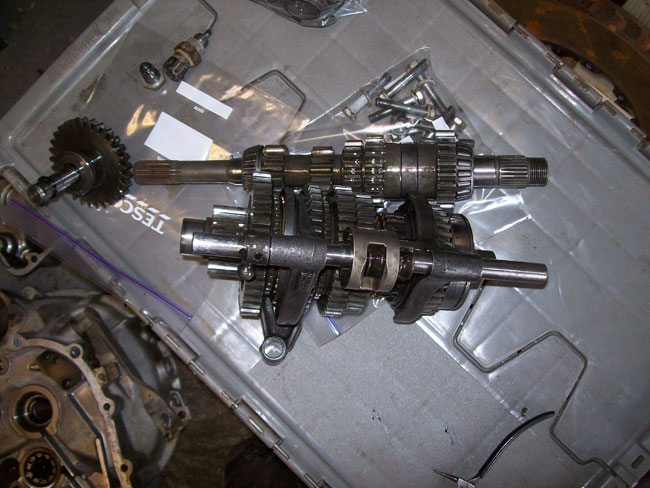

So, at the moment I have a bit of an enforced delay – I’m waiting for the pistons, liners and bearings to rebuild the bottom end of the engine. But one thing that I’ve never quite been happy with since I bought it is the Limited Slip Diff (LSD) that I have. Long-term readers may remember the DNF on Rallye Sunseeker 09 when the old LSD I had (which I never found the maker of) exploded on Stage 4, leading to a broken gearbox, an unhappy crew and a big bill. But the replacement Gripper diff has never really locked up in the same way that the previous one did, and as I have everything out, I thought it was time to investigate, so I stripped the gearbox to get access to it.

Again, long-term readers will remember that this is one of my least-favourite jobs on the car – splitting the gearbox is something I’ve never found too easy (and indeed I learned how to do it the hard way originally, making a right mess of the first box I attempted to dismantle). But with practice and a bit of thought then it becomes easier, and indeed when I got my Mum to hold a circlip open while I tried to move the casing it made it much easier – it was about 20 minutes to get the whole thing apart and the diff out.

Fortunately everything inside the box looks in good condition, and the problem on the Sunseeker with the oil leak (due to three bolts coming out as I’d not replaced the lower mount properly) had no effect on anything that I can see – all the bearings and gears look as they should do. An LSD is necessary in a performance car (yes, the Skoda!) to allow more grip and traction – the problem with a standard diff is that if one wheel has no grip (such as on mud, or in the air) then all the engine’s power will go to that wheel; I’m sure some of you have experienced this in a front wheel drive car when you try to turn and accelerate at the same time and the inner wheel just spins. The LSD stops this, but how much it does it by is part of its setup, and one thing you can measure is the pre-load on the diff, which is how much torque it takes to turn it. And the Gripper was set to 5ft/lb, which is WAY less than it should be, I believe (although I’m asking about as I’m not 100% sure) – I’ve read it should be more like 30-40 for my application.

So I set about taking the diff apart to see what was going on inside. I didn’t find anything of note, so I think this may be somewhat beyond me; if it was the kind of part you could take off and put on easily then I’d be willing to experiment, but it’s not for me, so I will be taking advice and possibly sending the diff off to get it set up correctly.

Other than that, no news really; I’m hoping to get the engine parts before next weekend, and get the engine built next weekend; I’d think the whole lot will be going back in the car the weekend after, which is largely on schedule. I’ll also be ordering the replacement drivers’ seat this week as well, which is the last significant expense (hopefully!) to get the car ready. Hopefully.

September 18th, 2011 on 7:15 pm

Darren did you buy those bits from Tesco ..or is that just a protector ?

Good luck on the parts ………

Will,,,,cheshire

September 18th, 2011 on 7:20 pm

Hi Will, not just sandwich bags to put the parts in and keep them clean! Wish the gearboxes were cheap enough to be from Tesco! Did you get my email?