Aftermath of a rally

by Darren on Mar.06, 2011, under General

A few people have emailed me recently mentioning the amount of work that goes into competing in a rally car, having been surprised at the amount of work that is needed to get the car ready and so on. So I thought I’d cover the other side of the coin – what needs to be done after an event, in terms of work on the car.

Before that, a quick summary – after Rallye Sunseeker, the car was pretty much unscathed – we’d hit a few things here and there, but there was no ‘proper’ damage – everything that happened to the car was run-of-the-mill. So the first thing to do (and this was done the day after the event) was to clean it – here’s how it came home:

And the engine bay looked like this:

So – certainly doesn’t look too bad in the pictures (although I think they make it look a bit cleaner than it actually was), but it needs to be clean, as the car will probably be stood up for some time (possibly until September, if not longer). Up on some ramps it went, and then it was time to jetwash the underneath – under the wheelarches, under the floor, round the suspension and brakes and so on. This took two hours of solid work – it really was that bad, and local mud is pretty sticky stuff. This left the road looking like this:

Which again may not come out too well in the photo, but after I’d moved the car, I used a spade to get as much as I could into a wheelbarrow, and it was over half a wheelbarrow full of mud! It really was dirty; the car also got a ‘normal’ clean with hot water and a sponge too, as the top needs to be clean as well, and at this point it looked OK. However, there was a lot more to do – the reason being is that the most expensive part on the car is also one of the most vulnerable in terms of corrosion, the suspension. Those with long memories will know that I bought it as part of a job lot of parts, and it was wrecked when I got it; it cost £1350 to get it reconditioned, and it’s transformed the car in the process. However, it can’t be left on the car; OK, it could do, but that would be a really stupid thing to do, as the mud and water would do it no good long-term, and I really need to avoid the expense aside from anything else.

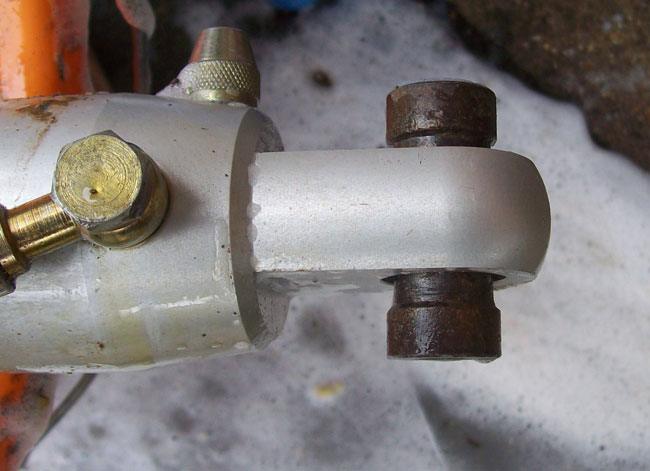

This weekend’s job has been to get the suspension off and cleaned up, so the car was put up on axle stands all round, and then front struts and rear coilovers removed, which is a fairly quick job as all the bolts have been off recently so nothing is rusted in place, and as soon as they get pulled off the car, you realise why jetwashing isn’t enough; the wheels and the car body get in the way meaning that you never get it completely clean. Here is one of the rears having been removed from the car and then having the spring removed:

Clearly filthy, and the mud would lead to lots of corrosion problems. So, half an hour’s work on the rears left them looking much better:

Once this was all done, everything could be checked properly (all seemed well), dried off and then sprayed with ACF-50 which is an anti-corrosion spray which I’ve heard good things about; typically used on motorbikes etc, I’m sure it will help keep everything looking good and working well.

It was much the same story with the fronts – they had a lot of grit and mud stuck between the springs and the strut bodies, so that was all cleaned out, and then the bottom of the struts was removed and the bushes checked; the oil that you put inside them when you assemble them (user-replaceable, as it were) looked to have done a fair bit of work, and it took quite a bit of work to get them all clean, but again once they were they looked good as new. They are now stored safely out of the way, ready to go back on the car when needs be – there’s no need to put them back on the car when it’s not going to be used, I think.

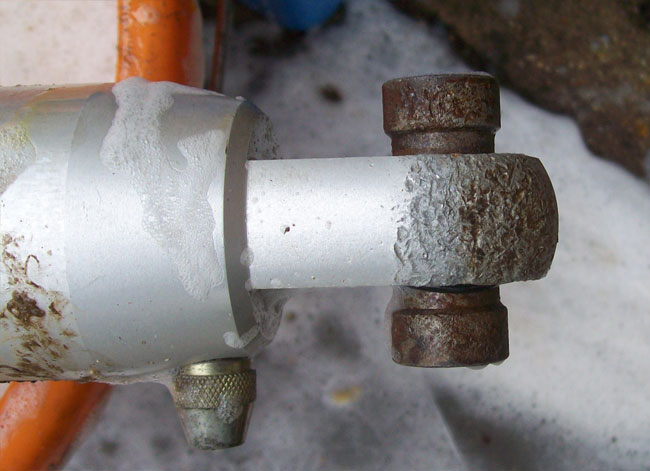

One thing struck me – the amount of damage that is done by stones to parts of the car; everyone who has seen the on-board footage has commented on the noise as we go along, which is of course stones hitting the underside of the car. And this was shown really clearly by the bottom of the one shock – it was brand new before this event, and looked a bit like this:

And after just a day’s use in the forests, this is what it looked like:

So you can see just how much abuse the underside of the car gets – it really is a harsh environment! However, the other bottom (which is much older) looks much the same, so I guess once the damage is done to a certain depth then that’s it, it’ll stay that way and not degrade too much more.

Overall, the straightforward post-event work means a weekend to clean the car up and then to give the suspension a once-over and clean it properly. I’ve made a point of making lists of things that need fixing after events (as rose-coloured glasses can so often mean you forget what was wrong), and here’s the current one:

- Rattle under floor – towards the end of the day, something was hitting which shouldn’t have been, so this needs to be investigated.

- Gear lever sealing – the rubber seal round the gear lever expired and was leaking water (and mostly steam) when going over any puddles.

- Sumpguard sides attachment – these proved troublesome during the service when I fixed the gearbox mounting, so will need to be made quicker and easier (and not cross-threaded, now!)

- Drivers door handle/fitting – it became harder to get out of the car as the day went on – the mechanism is tired….

- Passengers door handle/fitting – much like mine!

- Extinguisher Foam – I made a temporary foam cover for the plumbed-in extinguisher to stop my helmet/HANS getting damaged when putting them into the helmet net; this needs to be done properly.

- Water Leak – the car was losing water towards the end of the day from the tank cap.

- Starter Terminal – this just needs a new connector fitted, but it’s a really important one and is on/off a lot so needs to be top quality.

- Squeaky front suspension – the right front squeaked by the end of the day; this may have been fixed having checked the whole load over now.

- Floor protection – the floor is getting damaged, so I need to make up some kevlar guards to protext it and give the car a longer lifespan – same goes for the sills.

- Sumpguard mountings – the lack of adjustment in them nearly led to us being late or even excluded when leaving service on the Sunseeker, so I have come up with a better mounting system for them, which should give adjustment but also good strength.

- Exhaust leak – the manifold appears to have cracked, and needs replacement, really.

- Clock adjustment switch – a minor point, but the switch to adjust the minutes on the clock on the dash has failed, and I’m sure Paul was sick of me asking him the time!

- Damage to wing edges and seams under rear arches – there’s quite a bit of stone damage to the flanges of the wheelarches, these need to be straightened, cleaned and then painted.

- Welded areas in inner wings and towing eye (paint/rustproof) – some damage here too, which needs to be cleaned, rustproofed and painted.

- Replace fuel pipes in engine bay – they were the same age as the tank connections which failed, so this is preventative.

- Paint bumpers – cosmetically the car is looking a bit shabby because of the bumpers having lost their paint, so they need to look much better; not a big point but it makes a real difference to the car’s appearance.

- Fix windscreen water leak – if it rains the passenger’s side fills up with water – I removed half a bucket from it before Rallye Sunseeker.

- Re-route fuel tank pipes properly – the fuel tank pipe routing isn’t ideal so I want to address this.

- Extinguisher Service – they were last serviced in August 09 so will need to be done again if we are to compete in Rally GB.

- Replace driver’s Seat – The seat expires in June, so will need replacing if we are to do Rally GB.

- Check rear wheel bearings – these have been checked and are OK!

- Replace joint in gear linkage – the gear change is getting a bit sloppy as the joint in the linkage is wearing, so this needs to be sorted to stop incorrect gear selection.

- Gearbox check/rebuild – the loss of the three bolts led to some issues with the transmission so the diff bearings will need replacing and re-shimming, and the rest of the box needs a check.

- Engine rebuild – the bottom end of the engine is very tired, so this will need rebuilding, possibly using the 1400 crank which Skoda homologated in 1999.

So, as you can see, there are a fair few things to do! Obviously some are smaller than others, but they still mean a fair few evenings and weekends taken up with it all, and on top of that at the moment I’m not sure what I’m going to be doing in the future given the lack of a navigator for Rally GB and also having some problems with work (a long, regular contract which is about 35% of my work has ended),but I figure the best thing to do is to plan ahead and get as much as possible done so if the opportunity presents itself I will be able to take it.

March 7th, 2011 on 8:41 pm

What a solid – and unique – write-up, Darren. I think this post might get mentioned tomorrow… 😉