Seat

Titon Harnesses

by Darren on Feb.10, 2012, under Seat

Rallying is expensive. There is no way around it. But it’s made more expensive by some of the rules, which are under some dispute at the moment; while I got caught replacing the Ibiza’s seats shortly before the rule to make currently-FIA homologated seats (which means under 5 years old, at a cost of around £550 for a pair in my case, sometimes a lot more) compulsory was suspended, one thing that hasn’t changed is the requirement for in-date FIA harnesses. The ones in the Ibiza ran out at the end of 2011, which means that despite being completely serviceable and in good condition, they have to be replaced, adding to the considerable cost of rallying. They’re not cheap, and previously I have used Sabelt ones in the Skoda and they came in the Seat as well, but there is a local company called Prima Motorsport who make FIA-homologated harnesses, so I thought I’d do the decent thing and give them a try; I ordered them a couple of weeks ago but couldn’t pick them up until today. They came in a nice neat little box:

Opening them up revealed what I’d ordered – a harness with ends suitable to be wrap-mounted over the harness bars on the roll cage, which is a nice neat option and offers better angle of the strap over the shoulders.

On inspection, they were every bit as good as any of the higher-priced alternatives that I’ve used before, and indeed come with a really nice little touch – often it’s a pain to get your intercom cable to stay in the right place, but with a neatly-done bit of velcro (already added so with no scrutiny issues), it’ll be a piece of cake:

They came with a very clear instruction sheet, which shows the right way to install the wrap-over harnesses. When I removed the old ones I found that they hadn’t actually been fitted very cleverly, and the way the new ones are in will work much better. Setting them to the right length was a piece of cake (and easier than with other types I’ve done before), so overall, I have to say I’m really impressed with Prima’s harnesses – aside from the price and service (both of which were excellent), the product is great too. Obviously I’d rather not have to spend over £200 on a pair of harnesses that may only get used for 10 days in their lifetime, but with the obligation to do so it’s nice to know that my money has gone to a small and decent local business. Sermon over!

Every cloud…

by Darren on Feb.08, 2012, under Build, Seat

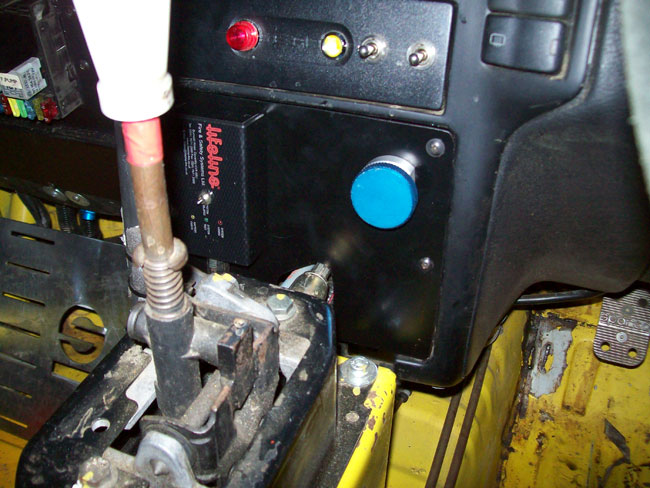

… has a silver lining. And today’s cloud was being off work! One of the schools I work at is a boarding school, and they had a dose of a vomiting virus, so they have closed the school. Which means I get a day off (yay!), but means I don’t get paid (boo!). However, there is no peace for the wicked, so I thought I’d make some use of today and get some more ticks done on the Ibiza’s “to do list”. Top of the list was the bias adjuster – I’d made the new plate up for the dashboard and painted it, but it needed fitting, and to do that I also needed to drill a small hole in the bulkhead for the adjuster cable to pass through. There’s not a lot of room in there to do it, or much access with the roll cage in the way, but thankfully due to a small air drill and clearance under the bonnet drilling the hole was easy enough, as was fitting a grommet and getting the cable through. With it all screwed in place and connected up, the brakes are now adjustable from the cockpit, should that be necessary.

That’s the blue knob, which is turned to adjust the bias front and rear.

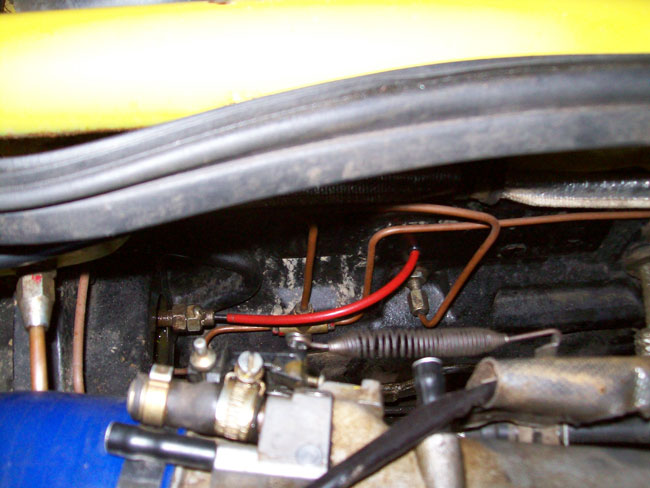

The red cable is the adjuster, which connects to the bias pedalbox which is seen on the left. Straightforward really (now it works!)

Next up, the terratrip. While I’d managed to fix the keypad on it, the battery inside it looked fit to explode, so I’d ordered a replacement Ni-Cad one, and fitted it without one in the meantime. The problem with this was twofold – firstly, whoever fitted the thing in the first place connected it to a switched live, so when you turn the ignition off, the trip meter goes off. Not a great idea, and secondly without the battery when you turn the engine over it has a tendency to wipe the terratrip memory out. Taking it all out of the car and apart again was a bit long-winded, and having “lost” the batteries I ordered made the job even longer; I’d actually put them in the “bits to fit” area of the garage and forgotten about it. Still, easily fixed, and soon enough a permanent live feed (although still cut off by the kill switch for obvious reasons) was wired in, fused and everything. With it all back together and the battery charged up for a while, it all worked as it should do, keeping time whether the car was on or off.

After the tank exploration last time out, I still had to re-fit the cover for the filler pipe. This, too, turned out to be remarkably easy, just taking a bit of care to do it had it fitted in a few minutes. Another thing taken off the list!

Next up was the guard for the alternator and power steering belt – I have no idea how it was supposed to fit with the sumpguard as it just didn’t fit – whichever you fitted first, the plastic guard just didn’t work properly, and looked more of a danger than a help, so I took it off and cut it down. Refitting it to the car showed I’d taken a bit too much off, but this was cured by heating it up with a hot air gun and bending it to suit the sumpguard.

While not a watertight seal, it is intended to keep stones out of a critical area, and looks to be doing just that. I may find a way to fix it to the sumpguard with a couple of screws/rivnuts to ensure it’s easy enough to remove but will stay perfectly in place; the other side has some mudflap material which needs the same treatment as previously it was held on with nuts and bolts (which must have been a real nightmare if you needed to do something quickly!), so when I come to do the oil change at the weekend, it will get all that done to it.

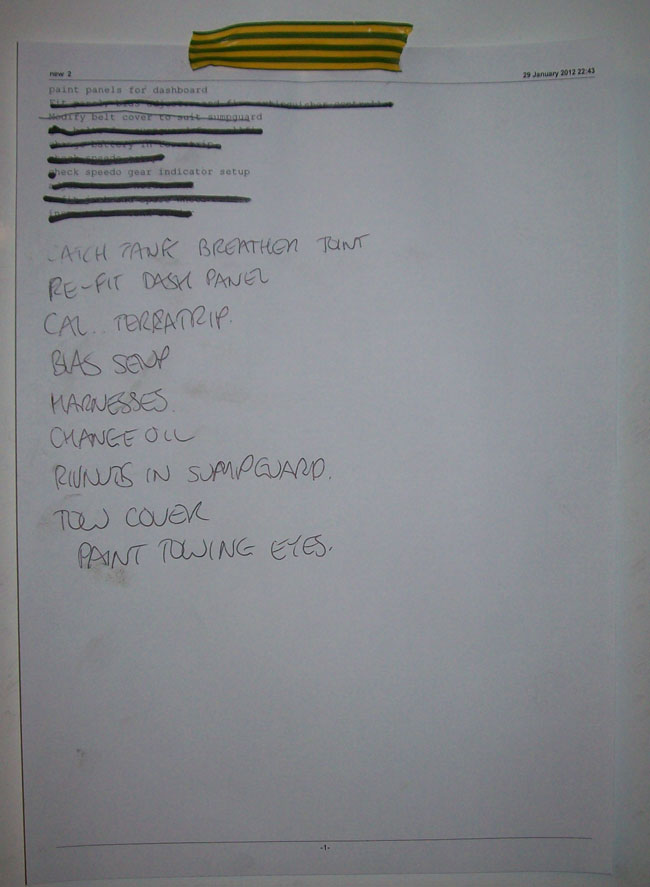

And that is about it! Doesn’t seem like there’s 5 hours work there, but with all the messing about that’s needed and going to buy parts (three trips to the shops, each time for tiny things), it all adds up. Still, the list now looks like this:

Which is a bit odd – I’ve done 8 things today, but added 9 to it. That’s progress for you! Seriously though, most of those things are straightforward. I reckon a few hours will see everything ready for the car’s first trip out on Rallye Sunseeker, entry for which was confirmed today by the organisers. There look to be a few entries in our class, so we will no doubt be slower than everyone else… or will we?

Cracking time part 2

by Darren on Feb.02, 2012, under Seat

Having the joy of a day off…. I decided to spend it working on the Seat! I have a small list of things that are needed before the Sunseeker, and although none of them are drastic, they’re all the sort of thing that can make the difference between a smooth fun day out and spending the day with bits all over the place and each service patching the car back together.

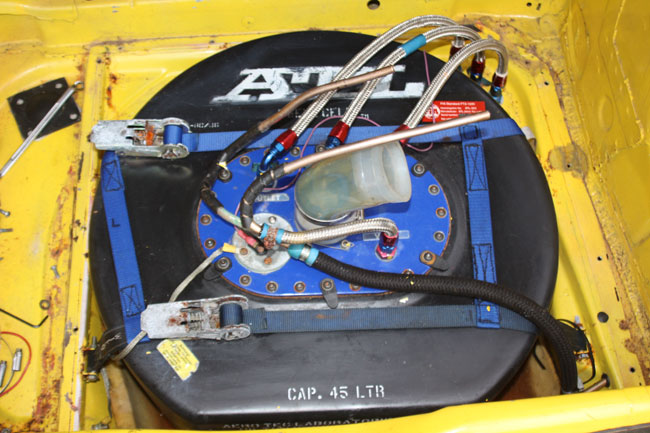

With that in mind, I thought i’d tackle the most difficult bit first, the fuel tank. While the fuel gauge seemed to work, I wanted to check it out fully, and while I was at it I wanted to check what condition the tank was in – it’s in an aluminium box in the back of the car (as per regs), and I had no idea what it was like inside there. It was a bit of a mystery how to get into it, as it’s quite well sealed up, with an aluminium tube between the filler and the box as well, and it took a fair bit of working out before it was all apart, but it was a pleasant surprise to find this:

One ATL tank – I had expected something with a composite outer and a bag inside, so I was pleased to see something less exotic which is less likely to give any trouble. Splendid. Next up was the sender – the silver disc at the bottom left of the blue access panel above – which I removed to check what the fuel gauge would read when the tank was empty. And it turned out it was worth all this effort – it actually shows about 1/8 on the gauge, which wasn’t what I was expecting. It would have been easy enough to run the car dry on the day, so now I know. I also know that when full it will show full, and that all the gubbins inside the case is in good nick. Putting it all back together was simple enough, thankfully.

While having a nose around underneath and replacing the sumpguard bolts, I noticed that one of the anti-roll bar ends was cracked; this was fine when the car was MOTed, but it was now in need of a fix. Once removed and cleaned up, it looked like this:

Easily fixed, but still would have been a problem if missed. 10 minutes’ welding saw it all fixed and once cooled back in the car.

Next up, the bias adjuster mounting plate. The original dash panels were a bit rubbish and bodged, so I made a new one piece one up out of aluminium and then painted it. The mountings in the dash still need to be sorted out, but it’ll be a lot better than what was there, and plus the brakes will actually be adjustable which is part of the point of having a bias box in the first place.

I’ve put an entry in for the Sunseeker, which is only a few weeks away, and the list is getting shorter, thankfully.

Brake Time

by Darren on Jan.21, 2012, under Build, Seat

With the Sunseeker coming up in just 5 weeks time, some progress was needed on the Seat. While most of it was OK, the brakes were definitely not the way I wanted them; they have been converted from the original servo-assisted setup to a non-servo bias-adjustable setup with individual cylinders for the front and rear, plus of course the massive AP Racing front brake setup. While this sounds impressive, it wasn’t in practice – an immense amount of pedal pressure was needed, which meant there wasn’t a lot of control. They were powerful, but to get the power you needed to put the kind of effort usually only seen in a final of World’s Strongest Man. Not a good combination, really, and even on a short stage it was tiring. Doing an 11-mile forest stage would definitely be ‘interesting’.

So, it was time to improve matters. First up was to remove any chance of a routine ‘service’ based issue giving these problems – while it was unlikely, it was worth checking anyway; so, it was time to change the brake fluid and bleed the entire system. The car had been laid up for a couple of years so the fluid needed changing anyway. With the old stuff syringed out of the master cylinders, a problem struck. The front brake calipers’ nipples were looking very worse for wear (a combo of having been mis-spannered and also beaten up with stones), and a couple didn’t want to come out.

Given that the calipers are £800 a side new, I didn’t want to mess things up, so bought an expensive wall-drive socket to give the best chance of removing them. And the £12 paid off, as they all came out OK. £4 then saw them all replaced! I’ve never understood saving money on things like this – it always comes back to bite you.

There’s a link pipe between the inner and outer parts of the caliper, and this was stone-damaged too, so that was replaced – another time I was glad I had a bunch of tools as making the brake pipe up took minutes to do. Then, bleed all the brakes, refit everything and go for a test drive.

Still terrible. However, in the meantime I’d done some reading about brakes, and found some very interesting info on the Stoptech website – in a very informative help sheet about such brake setups, it mentioned that the ‘pedal ratio’ of most standard setups was wrong when converting the system over as mine had been. The ‘ideal’ ratio is 6.2:1, so it was time to see if my setup was the same. I made some measurements, and found that mine wasn’t anywhere near – it was 4.3:1. This would mean that a LOT more effort would be needed to get the same pressure on the brakes, which made sense given the way the brakes felt.

In short, out came the pedal, and it was then re-drilled to give a ratio of 6.2:1 by making the distance between the pivot and the brake pushrod 40mm instead of the previous 58mm.

The new hole is B, the old hole is A, and the pivot is C in the picture.

I put it on the car (without reinforcing it yet) to see how it went. Fortunately unlike other pedalboxes I’ve worked on before it’s fairly easy to do, and within 5 minutes I was out in the car, and it was transformed. Still needed a bit of a push when cold, but instantly felt much better; the payoff is more movement in the pedal, but it feels fine now – before it was horrible, and now I have some real control – it was easy to take the brakes to the edge of locking up.

To finish off, it needed to come off, and then have some strengthening done – there was a hole right next to the new one, originally, which needed welding up, plus the inside of the pedal was also only single-skinned so this was beefed up, painted and then refitted.

The errant starter motor was next, a quick grease of the appropriate bits freed it up – it’s not perfect (although it looks like new on the outside, it was clearly badly reconditioned!), but it works OK and doesn’t stick now.

The car is pretty much all set now, I just need to fit the bias adjuster, making up a new plate to mount it in, but that can be done tomorrow. One thing I did notice on the test drive is that it really does go well! The Sunseeker should be magic.

A cracking time…

by Darren on Dec.23, 2011, under Build, Seat

It’s been a few days, but a long few days, so I’ll start at the beginning. Last time out the Seat had the standard head re-fitted and everything in place for the first time since I bought it, and Monday morning meant enough time had passed to get the battery charged up, so it was time to see if it ran. Before the strip down the engine was running well, and indeed as soon as it was warm it would tick over like a real car. But it had been a long time, so I was pleased as punch when it fired up on the first turn of the key, and sounded sweet. Splendid. However, there were still some bits to re-fit – I’d not fully filled the coolant, or refitted the drivebelts for the alternator/water pump or the power steering, so these went on in short order and I fired it up and left it running; after a couple of minutes of throttle blipping it ticked over quite happily. The exhaust sounded quite different to when I bought it without a huge hole in it – it’s quite a quiet car. Or rather it would be, if there wasn’t a problem. When I bought the car, it came with a spare front pipe (which includes the cat). I nearly sold it at one point, and I was glad I’d not done so, as the flexible joint on the one on the car had split, so the car had that horrible sound when there’s an exhaust leak near the engine. Clearly that needed fixing, and it would have been better if I’d spotted it with the head off. I went to check on the disks which were being machined back to spec, but they weren’t done, and the weather turned, so that was the end of Monday. On Tuesday I had to work, but on Wednesday I went to pick up the brake discs (which still weren’t done), as I’d taken the bold step of booking the car in for an MOT on Friday. If you don’t set a deadline, then projects just go on and on, and it was time to get the Seat finished. I cleaned the discs up with wet and dry and they came up very well. I then fitted them to the mounting bells to find out the originals had been fitted wrong according to AP’s site, so that was nice! Cleaning them up, fitting them to the car and refitting the calipers and pads took up the whole morning, and just when I thought I’d finished, I noticed this:

A couple of cracks in the inner wing. They were mostly the result of the metal being brittle where it had been seam welded, although there was one small patch that needed new metal as it had rusted. Not too bad to do, and half an hour later, it looked much better:

Much better and no problem for either MOT or actually driving the car. I took a precautionary look around the rest of the car but didn’t find anything else like it, so hopefully it was just a minor issue. After that it was time to fix the exhaust.

This was a complete pig of a job. Whoever designed the downpipe for the Ibiza (or rather the gap between the steering rack and the body) needs to be dispatched. What could have been a straightforward job was a complete pain to do as getting it out required a mixture of precision and strength which was incredibly difficult to manage with a car jacked up in my drive. I’m sure on a 4-poster it would have been downgraded to just “I hate this person, and the should suffer a lot”. I was eventually rewarded with a removed downpipe, and now I had to make one up. Eventually I took the path of putting the motorsport cat onto the new front pipe, which took a fair bit of grinding and cutting to get it off, but it was OK. Careful measurement and photography meant I could get the new part made up to the right dimensions (as there was a fair bit of play between the pipes), so I did a few test TIG welds and had to … refit the bloody thing to check it was OK. This was done, but again was hard getting it in, and harder getting it out. I fully welded it, and fitted it, and was relieved to find that it all fitted up without issue. And when the car started….. as quiet as a mouse, at the front anyway. This was a good thing, but the entire day was taken up!

Thursday was mostly taken up with collecting my Sister from Heathrow, but in the afternoon I changed the front tyres over to the MOT-legal winter tyres which were fitted to one set of tyres for the car, and then adjusting the handbrake cables and final fitting them, and fitting winter tyres. Once more play was stopped by bad weather and it being pitch black. Just time for a quick first test drive. The first thing that hit me was that the clutch is heavy and bites rather viciously. The second was nearly a roundabout – the steering is just 2 turns from lock to lock, and as a result I rather over-did it when I went round a roundabout, but fortunately corrected in time! The third was that the brakes needed a good push to work well, but other than that it was OK. A couple of runs up and down the road, and then I noticed the water temperature was getting a bit high, so I went back home, and found steam coming from under the bonnet! Not good, and a bit of a surprise as it hadn’t done it when run up to temperature before, but there you go. It was quickly traced to a not-fully-tightened jubilee clip, and I hoped that no damage had been done – the car didn’t get too hot, thankfully; the joys of proper instrumentation (the car has oil pressure and temperature as well as water temperature, and I think the Skoda should follow suit at some point).

So, today was MOT day, but in the night (as you do) I’d remembered a couple of things I’d not tightened up – just the lambda sensor and coilpack so easy enough – and also needed to sort the wipers out (which cleaned up OK), fit an interior mirror and fit new sill stand guards. Once more it was raining, but an hour saw all these done, along with the water topped up. Another test drive showed that all was well.

I hate MOTs. They are like scrutineering, but even worse. And as I’d booked it for 2:30 I had a fair bit of waiting about to do, which didn’t help. But it all went OK. There were a few advisories on it, nothing serious, and a PASS! So the Seat is finally ready to drive. Driving it back I took a few chances to give it some beans, and it goes OK. The brakes still need a firm push, but I’m hoping they are just bedding in at the moment (although they are non-servo) – they certainly stop OK, and warm up as well. The hydraulic handbrake is excellent, and the raised gear lever is really good – no more dipping out of sight to change gear, it looks more like one of the early manual-change Focus WRC cars (although obviously isn’t sequential!). It didn’t miss a beat on the way there or back, and that’s all I can ask for really. So it looks like a car change for Longmoor will be in order. How splendid. All I need to do is put the sumpguard on, get some tyres changed over and give it an oil change. But that can wait until next week; I’ve not had a moment to myself this week, so I’m going to enjoy Christmas for a few days instead. Happy Christmas to you if you’re reading this before the day, and even if you’re not, in retrospect.

Clearly it wasn’t the Skoda…

by Darren on Dec.15, 2011, under Seat

… that was cursed. By now, I should have a running Ibiza, and have it ready for the MOT. And therefore for Longmoor Loco. But as you may have surmised, I don’t. I’ve had a long delay with the ported cylinder head – the company doing it said they’d done one and then found a crack on final testing, so another one was needed. During the long wait, I had bought a standard head on eBay (just in case), and then the guy who was sending it forgot to mention it would be another week before he could send it. Great.

Anyway, on Monday the ported head arrived – unfortunately I was out at the time (helping a friend of my Mum with a problem with her car that turned out to be a blown head gasket), so didn’t get it until gone 5pm. I got it all unpacked and ready to fit, and then on Wednesday started looking at fitting it. I’ve never timed up an engine with two cams on it before, so a bit of research was done before I got started, but it all seemed simple enough, and having a spare head with no valved fitted made it easy to check out what was going on. Next up, time to get the cambelt off and everything ready to fit, which sounded simple enough, but took an hour or so to get it all done and the timing marks checked properly. And time to bolt the head on, which was easy enough – the engine has an ARP stud set fitted so it was nice and easy to put on, and it all torqued up easily enough.

Unfortunately I then had to ‘pop out’ for 3 hours or so to check out a replacement car for my Mum’s friend, so that was half the day taken up, and then time to put the exhaust on, which was easy enough too. And next up, the camshafts. The studs for all the cam caps had been removed for machining, so it’s a laborious job to put them on, so while I procrastinated for a bit, I decided to check out the camshaft caps. And found a problem. A big one. One of the caps is from another head. They are all numbered, and when they are made, they are bolted in place and then bored; it’s not possible to get a spare one as they are machined as a set (head and caps are matched). The ‘replacement’ one was from another engine, and nowhere near right – it’s about half a mm out of line at the parting line.

So far I’ve heard nothing in response from the company that did the porting, via email or phone. Great.

However, today the ‘standard’ head has arrived. So it looks like Saturday’s work will be to remove the head, get the standard one fitted and see if I can get the car running. I’ve also been to the machinists today to chase up the brakes which I’m having reground because they had some water damage (these were brand new AP discs), they should be ready on Monday. I have most of next week off (well, 3 of the 5 days), so hopefully it’ll be up and running soon enough, but getting it MOTed in time looks like a real stretch. We’ll see…

On the upside, I have tarmac tyres fitted to enough Skoda rims to do the event anyway, so plan A is all looking fine anyway.

Bits and pieces

by Darren on Nov.20, 2011, under Seat

A quick update. Firstly, I have a confirmed entry on the Longmoor Loco stages, which is held on the 30th December. A 2WD-only event, it’s always popular and is apparently great fun. It’s going to be my sister’s first event as a navigator, so it should be a laugh if nothing else!

Next up, I’ve done a bit of work on the Seat this weekend; as mentioned before both sills had some damage, which was really accumulated stone damage which had then been left to rust a bit; all surface rust really, although the rear half centimetre or so of each sill had a little hole in it, so I made up some nice repair sections and have welded them in, then cleaned up the entire sill and they’ve been painted. It’s very handy that Cupra yellow is pretty close to Hammerite yellow – later on I will paint them with the correctly-coloured paint but at the moment I’m more worried about protection than aesthetics. The sills could do with having fibreglass guards made up, so I may take this on as a project at some point, particularly as I have a bunch of matting left in the garage from another project.

I’ve got a flowed cylinder head coming the weekend after next, so with any luck the car will be up and running soon, which will be good; I’m really hoping to get it all done and MOTed before Longmoor, and if possible I may do the event in that, but more than likely it’ll be the Skoda. But alas another week of work beckons, so little if anything will get done until the weekend, other than the Terratrip 404 which I’ve removed this afternoon to check it over; it seems most of the buttons don’t work well and it beeps constantly so I’m going to see what’s going on with it!

I am a traitor.

by Darren on Nov.17, 2011, under Seat

In a decidedly non-chronological manner, I am now going to bring you up to speed with a new project, something which the eagle-eyed may have spotted in the odd photo here and there, and that’s that I’ve bought another rally car. I am a traitor, however, as it’s not a Skoda!

First up, at the moment I am keeping the Skoda; I’m still on for doing Rally GB 2012, and the Skoda is the car to do that in, as the new car’s homologation would have long expired, and it’s not in a homologated spec anyway as far as I can tell. I also still harbour the idea of doing an IRC round at some point (although as the Monte is back in the WRC, that pipe dream has fallen by the wayside). But in the summer I had saved up about £2000, which I was going to put towards a new bottom end in the Skoda; this would have covered a 1.4 conversion, better rods and forged pistons, so the bottom end would be good for 8500rpm or so, and allow the head to fully perform; it would have hopefully gained me about 25-30bhp or so, and made the car a bit of a rocket for what it is.

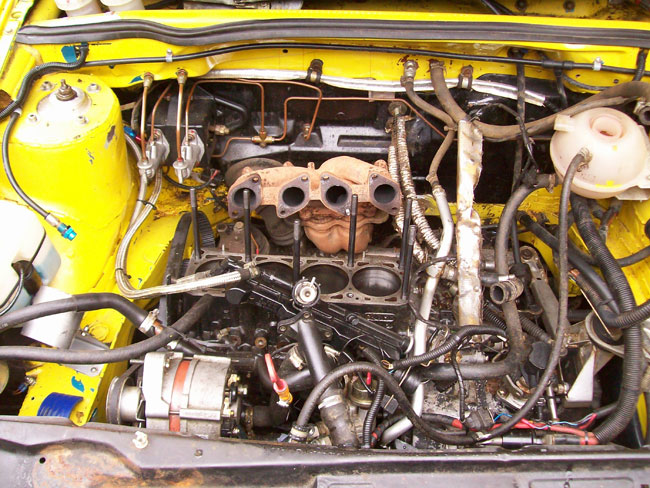

But while I was thinking about this, something popped up on eBay. It was a Seat Ibiza rally car, which looked interesting; fitted with a 2.0 16v engine, with a lot of ‘nice’ bits fitted; a custom cages weld-in rollcage, AP front brakes, Bilstein suspension, a close-ratio gearbox, Quaife diff, quick rack and lots of little details that looked good. It wasn’t too far away (about 70 miles), and worth a trip to take a look – in the advert it looked a bit of a shed, as it had been stood for a while, and had scars from its last outing on the Sunseeker 18 months beforehand, with broken front and rear bumpers. Long story short, I got it for a bit over two grand, but with a huge amount of spares thrown in – enough to completely (and I mean completely) fill Mark’s van when I went to pick it up. It had a few issues (all declared) – head gasket leaking oil, a cracked oil cooler, handbrake seized up and a few other bits and pieces, but it ran well. Here’s what it looked like when I got it home:

And inside it looked like this

Nicely done inside with a proper upright hydraulic handbrake (retaining the mechanical one for the MOT and scrutineering), raised gear lever tower, Terratrip 404, digital dash (which does datalogging and all sorts), plenty of gauges and so on.

On the downside, the seats were out of date so would need replacing, and there were a couple of holes in the floor that had been drilled to let water out (the car lets water in, alas), and the floor was a bit rusty with surface rust. First thing to take care of was that, so soon after it looked like this:

Next up, the handbrake needed sorting, which was straighforward – the cables were damaged and had rusted, so £20 saw that fixed – fortunately they were standard items and dead easy to change, particularly as the car has the tank in the boot (an ATL bag tank) so the standard tank isn’t in the way. The thing I noticed while doing it was that everything seemed to have been done to a high standard – there were no bodges or anything like that, everything looked really well thought out and engineered.

Obviously the bumpers were a real mess, so they needed to be binned, and fortunately I got a pair from a breaker at a good price, and replaced them and the mudflaps, taking the opportunity to change them to black instead of the original blue, and getting them up to current MSA spec.

The oil cooler was cracked, and luckily £50 saw a Mocal one to replace it directly, much better than saving £10 by buying a cheap one and then spending hours making new mountings and worrying about it falling apart. The front brakes were in a sorry state – one had been replaced by a temporary one of a different size, but spares were included. Unfortunately they had been stored without protection so they had a bit of surface rust on them, so they have been dispatched to be surface machined, and the pads have been replaced. The AP calipers on the car are ENORMOUS – the kit with discs, pads, calipers and mounting bells is around as much as I paid for the car! They should stop the car really well, and it has a bias box which will have a remote adjuster fitted (included in the spares, handily).

The exhaust had a break in it as one of the mountings had ripped a section of pipe out, so this was replaced; typically a perfect-looking bit of welding on something that will never be seen, but hey ho.

Finally (at the moment), the head. The engine has been fitted with ARP studs, but was leaking at the head gasket. The head had been replaced (originally it was fitted with a ported one, but had some problems) with a standard one, so once I’d removed it I took the decision to get a better/ported head fitted. Unfortunately time and so on has got in the way, and it’ll be a couple of weeks until I get the head back from being done; although it’s cost a fair bit more money there’s not much point in not getting the most out of the car from the start, I think. It’s fitted with a set of Kent Cams and was seeing nearly 200bhp, so this should be achievable with that combination, and should make it fun to say the least.

The last thing at the moment is the sills – they had a lot of stone damage, and surface rust as a result of being left for so long; I have stripped and painted one side and have the other to do, but both need tiny repairs at the very rears which should be a morning’s work and no more.

So, as it stands, there’s a few days’ work to go to get it all back together, once the head returns, and then I want to get it MOTed as soon as possible. There’s a possibility I may be doing an event before the Sunseeker as a shakedown as I’d hate to have a small issue cause a problem on it, but whether this happens will all depend on if everything goes to plan. At the weekend I’ll get some decent pictures of the car as it stands, and hopefully get the sills finished off.