Author Archive

That’s it, that’s all.

by Darren on Oct.09, 2011, under Build

Well, after yesterday’s disappointment, another chance to run the car for a weekend and get it mapped was lost before the closing date for Rally GB entries. This delay means that I’m four weekends behind where I wanted to be – mostly delays from Jorily’s incredibly poor handling of my order (taking over a week to give me a price for a part, and then nearly 3 weeks to actually deliver the parts when ordered, despite a two-week period where I was told it had been sent but hadn’t), but also the latest problem with the oil pump/front cover. Having spent some time thinking about it and discussing it with Bryn, we have decided that we will not be entering the event this year. Needless to say I’m gutted having spent a considerable amount of money getting the car ready (over £1000 at last count), and of course Bryn had been preparing too, getting himself a medical so he could upgrade the licence, but with the small amount of time before the closing date that’s it, that’s all.

I’m still going to get the car ready, having already ordered the last (£3!) part needed to finish it off, so if the oil pressure issues are sorted then I’ll get the fuelling mapped up next weekend, and take it from there. I may enter the Tempest Rally as I’d like to make some use of the car again this year, and the entry closes half way through half term, so I could competitively use the car before Rally GB. Other than that, I’m not sure what the future holds – the car is eligible to do Rally GB 2012, and if all goes well will be completed with about 10 months to spare (as it runs in September 2012); the Sunseeker will be done in a different car, in case anyone is wondering, and there will be more to come on that front in the coming weeks.

The path of my life…

by Darren on Oct.08, 2011, under Build

… is strewn with pats from the Devil’s own satanic herd, to quote Edmund Blackadder.

Yesterday, the new oil pump and pickup pipe that I ordered were due to turn up. However, the supplier didn’t get them in time, but after a phone call to them to ensure they knew how important these parts were and that they had to be with me today, they were sent special delivery, turning up at 8:30am this morning. Opened the box, and this is what I saw:

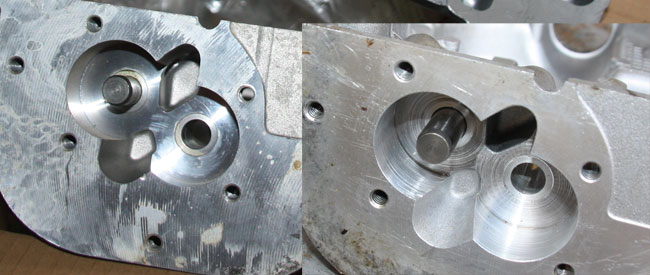

At the top, the oil pickup pipe. At the bottom, the engine front cover, which houses the oil pump (the two round sections where the gears go). The old pickup pipe’s pressure relief valve wouldn’t even hold me blowing on it, while the new one certainly does, so it seals 100% and that’s what I was hoping – it came with spring and bearing fitted, thankfully. Splendid, it was time to get started. I got out in the drive, got the sump off (placed back temporarily after stripping the engine the other day), and then set about removing the front cover from the engine. This is fairly simple, but means dropping the engine down to get the crank pulley off. Thankfully Skoda have thought about this and the engine mounting bolts are long enough to just loosen off and drop the engine the required 20mm or so. It all came apart easily enough – good music on the radio, everything going as planned. Finally looking like a great day for the Skoda. Here you can see the difference between the new (left) and old (right) pumps – the body is quite scratched, which will have an effect on pump pressure, plus the new one has much lower clearance whereas the old one was nearer the wear limit.

Where the crank comes out of the front cover there is an oil seal, which I have a couple of spares for, so I went to fit it and hit a problem. The hole for it to go into was too small. I couldn’t believe it, so I checked the seal I had against the cover that had just come off – it was the same size, 58mm outer diameter. There had to be some mistake, so I measured the hole.

Oh. Well, needless to say I thought more than just “Oh”. After I’d regained some form of composure I took a look at the old bottom end. 58mm. The other spares I have, 58mm. Clearly I’d made a mistake, so I checked the online parts catalogue from the page I had ordered it from, and checked the seal size quoted there. And it was 58mm. Not the 56mm of the casing I had. After some checking online, I discovered the problem. The part I have been sent is not the part I ordered. It was one from an earlier car, a RWD Skoda, and although the engine is the same, there are clearly some detailed differences and this is one of them; the earlier engine’s oil seal has a 56mm outside diameter. I think what’s happened is that the part is old stock, someone has found it without a part number and mis-identified it from a catalogue. Needless to say I will be letting said supplier know of my displeasure. I phoned several Skoda garages in reach, none of them had either a parts department that was open, or the part in stock. No bearing factors are open locally on Saturday, so there’s no option to get the oil seal.

Bugger.

So there’s no way the car can run this weekend. I can get the right seal easily enough either online or locally by Tuesday, but that’s too late. However, I decided to use the time I have to get everything back together as it’s possible to fit the seal in situ, so I spent the next hour or so putting everything back together – the new cover went on easily enough although my brackets for the crank sensor needed a small mod to the spacers (OK, washers!), and everything else fitted as it should do – pickup pipe and sump going back on without any issues.

The car can’t be run until Tuesday at the earliest (I work until 8pm or so on Mondays so nothing will be done then, alas), so I guess I’ll have to see what’s going to happen; I’m still not 100% sure I’m not at home to Mr Cockup, despite having found the problems which Jim had predicted, so I think a decision will need to be made soon about Rally GB. Stay tuned, and keep your fingers and any other appendages crossed.

The investigation begins…

by Darren on Oct.06, 2011, under Build

So, last time out, I had an engine that ran well, but didn’t have much in the way of oil pressure, particularly when hot. Not great, and clearly needing sorting out. I’d asked about and had some info from Jim Jones (who knows pretty much everything about Skodas) who said he suspected the pressure relief valve or the way the pickup was seated on the oil pump body. After finishing work today I thought I’d make a start on checking out what was going on. First up, the sump needed to come off; as it had only been on there for half an hour of running or so it came off without issue once the oil had been drained, revealing the bottom end in all its glory. I thought it was best to check all the bearings, and this can be done with Platigauge which allows you to accurately measure the bearing clearance – it’s like a thin strip of plasticine which you put in the bearing shell, bolt it up tight and then undo it, and measure how wide it has spread against a measuring sheet to see what the clearance was. The Skoda engine has 7 bearings in total – 3 main bearings and 4 big ends, and all the mains checked out OK, and big ends 1,2 and 3 did too, but No. 4 looked to have got a bit hot – it wasn’t terrible, but the bearing looked pretty worn. The crank looked fine, and amazingly (again!) I had 2 suitably-sized big end bearings in my box of bearings (from previous engines), and they fitted perfectly. Phew.

So, it looks as if the crank bearings are all fine, so why the low pressure? Well, now I seem to have removed the need to take the engine out, it was time to look at the pressure relief valve. This is part of the pickup on the 136 engine, and consists of a ball bearing and a spring – the bearing seals a port in the oil pump, and once the pressure gets too much then the spring lets the excess pressure out. If this valve leaks, then the engine will not have good pressure at idle, as that low down it needs as much pressure as it can get and can’t afford to leak any. So, I took it apart, and it looks as if the sealing area where the ball seats is rough – indeed it wouldn’t hold my breath when I tried to blow through it, even with the spring pressing hard against it, so hardly likely to resist much in the way of oil flow, I’d hope.

Either way, I have a new pickup and oil pump body arriving tomorrow, so hopefully when I put the spring and ball bearing into that, it will stop the flow, and in that case, it may well do the trick. Here’s hoping…

A long weekend…

by Darren on Oct.04, 2011, under Build

… starts on a Friday afternoon. After the previous day’s debacle, I had arranged for the engine to be taken back and a full refund. But this of course meant I needed to build the other one, and the parts had arrived. The first task is to change the main bearings, which was done in short order as the whole engine was in bits. Oiled up and with the crank in place it turned over easily, which seemed a good sign, so I then got on with the least favourite bit, getting the liners in; they are free in the Skoda block, and they need to be shimmed to the correct height above the deck and also relative to each other. This is a slightly tedious process and it took an hour or so to get them in correctly. Next would be fitting the pistons to the conrods, which should be straightforward, but I wanted to check the pistons were OK, and found… a problem.

The piston/liner set I’d been supplied with had been made up from a set of liners with different pistons as my engine is a 136 (high compression), and the set the supplier had got was a 135 (low compression) set. And checking the pistons showed that they weren’t all the same size. Normally, this would have been a case of the fat lady singing on the engine, but as luck would have it, I had a single spare one I’d bought years ago and stored, and it was the right size! How convenient. So with that luck out of the way, the rest of the engine was built up – conrods on pistons, rings on conrods, pistons into bores (carefully to avoid any issues like before), and then finally conrods onto the crank. Within an hour or so, I had a working bottom end. Camshaft was now fitted and it was time to check the timing – manufacturing tolerances can mean all sorts of issues with cam timing, and this is a crucial setting that determines the engine’s performance and character. Mine needed to be with the inlet valve reaching maximum opening at 108 degrees, and I was finding it difficult to measure accurately with the head off, taking the measurement just from the cam, so i needed to fit the head and then take it from there.

Unfortunately, an error occurred here which cost me a lot of time – I have a ‘degree wheel’ fitted to the crank, and I managed to disturb it by turning the engine the wrong way and loosening the nut that held it. This happened after I’d fitted the head gasket, so I needed to measure it accurately again which meant I had to make up a special tool to allow this, and then re-set the wheel accurately. Another two hours gone, but thankfully the cam was timed up perfectly. Last time I needed to make up an offset key, and that took me a couple more hours to get right.

So, I finished building the engine, fitting the oil pump, sump and other covers, and got it bolted to the gearbox in time for lunch. Splendid, I was back on course.

After lunch, I fitted the engine to the car (with mum’s help as ever), and the properly-jointed exhaust manifold made fitting much easier as I could take it off, fit the engine/box and then fit it afterwards, rather than try to get it on and then lift the engine into place. Everything else went pretty smoothly, and 2 hours after stepping out the whole lot was back in the car and ready to run.

But would it run?

In short, YES! It fired up near-instantly, and this was despite me accidentally leaving one of the injector plugs off so it ran on 3 cylinders briefly. With that fixed, it fired up without hesitation, and I revved it up a few times and held it at various RPM as people suggest with a new engine. All seemed OK aside from the paint on the new manifold burning off (it looked like the car was on fire at one point!). A few more checks and changes and it was back on its wheels and ready to drive, but I called time as I was pretty tired.

Sunday saw me drive the car for the first time, and it moved without issue; I could instantly feel (and hear!) the diff working when I moved it, and with everything double-checked I went for a first drive. Several things were noted; firstly the car ran pretty well considering it was mapped for the old camshaft, not the new works one that’s fitted now. Secondly, there was still a lot of smoke (which turned out to be because the dipstick was the one thing I’d forgotten so it sprayed oil directly onto the exhaust – no big deal once I’d fixed it). But thirdly, I had a problem. There was no oil pressure at tickover once the car was hot. This had been a problem before with a couple of other engines, and given the new bearings and so on I wasn’t expecting it. However, I thought it may be that the oil was getting hot, so I fitted an oil cooler (which I handily had, I’d never fitted it), but alas this didn’t make too much difference (although it won’t hurt when in competition, I’m sure).

I have done some asking on the rally forum and the general consensus is that thicker oil (such as 10W60) will sort it, and also that I should take a look at some of the oil pump mechanism where the oil gets sucked in and the pressure relief valve. I’m erring on the side of caution and have ordered a new oil pump body (the front cover of the engine makes this part up) and a new oil strainer/sucker to hopefully eradicate this permanently with all three. If not then there’s clearly a problem with the crank bearing clearances, and if that’s the case then I will have to get a regrind done; I have a spare crank which can be ground down to the current size I am at with this engine, so I am not despairing (yet!), but it’s not ideal as it will mean engine out to get the crank out, so another weekend’s work in total to do that. I really hope it doesn’t come to that…

An interesting day…

by Darren on Sep.29, 2011, under Build

Today was the day a number of things were due to arrive – the main things being the now-serviced fire extinguishers, and also the ex-dealer stock un-run engine I’d bought as an insurance policy to get the car running again. Mum had kindly agreed to stay in all day, so I went to get her the papers before I went to work, and I came back to a surprise – not only had my engine parts finally arrived from the Czech republic (pistons, bearings, liners, etc), but also my rear shock is back from Proflex, fully rebuilt! Excellent.

During the day, the fire extinguishers were delivered, and the engine turned up. I got back from work around half four, and unwrapped the engine. And to say the least, I was displeased. Despite speaking to the guy on the phone and being told that the engine I was getting was the one I’d seen on eBay, let’s play a bit of spot the difference, shall we? Here’s the engine on eBay:

Clearly a newly-built engine; the flywheel (on the left) is bright and shiny and hasn’t been used. The ports in the head (at the top) are clean, so it looks like this engine has never been run. Which was as it was advertised. This is what turned up.

Clearly not what was advertised. Rusty, had been run, etc. This is an old engine, maybe worth £50. Certainly not worth anything to me. Long story short (after a heated phone call and some eBay based complaint action), it’s going back for a full refund, but I’ll still have wasted £50 on delivery to me. Displeased.

Still, move on, nothing to gain from dwelling on it. As the pistons etc had arrived, Plan A is back on track. The first part of this was to rebuild the diff to the correct preload. I’ve been fortunate enough to have some advice from the ever-excellent Steph Rowson from Motorsport Transmissions and with his guidance and the parts from gripper it was straightforward to get the diff to the right preload; all it took was one plate in the diff being replaced with a thicker one (I’d ordered all the sizes they have as they are only £3 each), and once reassembled it was working properly at the right torque (which will drop off a bit as the plates bed in). Splendid. Next, getting the box back together, which was easy enough too, particularly as I have a proper Skoda workshop manual for it.

Now just a bit of time to do some work on the bottom end of the engine. This was one I built in 2008 that had a cracked piston land; the bottom end itself other than that was fine, but I’ve changed the main bearings and put all that back together this evening, and it turns over a treat. It’s now got an ex-works cam in, and at present that’s how it’s stood; tomorrow afternoon I’ll get a couple of hours to work on it so I’ll have the horrible job of getting the liners fitted into the block and shimmed correctly – it was a real pain in the bum last time. Here’s hoping second time will be better.

Progress…

by Darren on Sep.27, 2011, under Build

… of a sort has happened. Not as much as I’d have liked, but some.

So, the deal was this; I’m waiting for engine parts to rebuild a bottom end to put into the car, and for plates to allow me to set the diff to the correct torque. Despite being told that they’d all been posted by both suppliers, it now transpires that they hadn’t. I was told that the engine parts had been sent on the 13th September. Turns out they were actually only posted (in the Czech Republic) on the 23rd (i.e. Friday just gone). No wonder I’ve wasted time waiting for parts to turn up. I have no idea when they will turn up, as the tracking number I’ve been given doesn’t work and the supplier in question has gone quiet. There are also some technical concerns as one part has been substituted so I don’t know if they’ll be the right clearance anyway. So, I needed another plan, and it should be arriving on Thursday, in the shape of an ex-dealer stock engine which is apparently rebuilt and unrun. It will need a new cam on it anyway (as I have a works cam I want to run in the car), and the head changing, so most of it will be inspected as a matter of course. It’s also an opportunity to get a new oil pump and a number of other parts into the bargain. Hopefully. All will be revealed on Thursday when it arrives and I have some time to check it all over. Yes, it’s out on a limb, but at this point I’m not in a position to go ‘all in’ given the delay that could happen with the parts I’d ordered.

As for the diff, it turns out the parts were only posted yesterday (as opposed to last Wednesday, which I was told they would be going out on when I ordered them), but they are at least here, so it should be a couple of hours’ work to get the diff set up to an appropriate breaking torque, and then get the box back together.

In the meantime, some suppliers have been good to their word. The ever-efficient Larkspeed have delivered the replacement driver’s seat (a Cobra Imola Pro, replacing the previous Imola S), on the day they said they would, bang on 9am. This is now bolted into the car, a 5-minute job which left me hoping everything else would be that easy (it won’t!).

Lifeline have serviced the 4.0ltr plumbed-in and 2.4ltr handheld extinguishers, and they will be back on Thursday too; another item which is just bolt-in and forget, which will be pleasant. Having to have perfectly good extinguishers serviced at a cost of £90 every two years isn’t (for FIA events they need to be tested and stickered by the manufacturer). I’ll check up on the rear shock rebuild status tomorrow, although I know Proflex were busy when I phoned them, and I’m not in a hurry for it back, but it’s another thing to not worry about.

Shiny!

by Darren on Sep.25, 2011, under Build

So, there were no new parts appearing this weekend, so I couldn’t do what I’d planned, build the new bottom end, sort the diff out and put it all back in the car. The parts I’ve sent off are where they need to be, being serviced (fire extinguishers) or rebuilt (rear damper). I’ve ordered the replacement driver’s seat, and put the other one on eBay to get some money back from the £400 it cost to replace it(!) – it’s in excellent condition, you’d really not think it had been in a rally car for 5 years.

This left me wondering what to do, so I consulted the list, which is actually thankfully quite short; the bits above are just bolt in items, with the majority of the work being the engine and diff; the rest of the car has a number of little issues which need sorting, and I’ve ordered the parts for them, but one thing could be done – making the car look better by sorting out the bumpers; They were painted in 2008 (by me), and have never looked great. Two Rally GBs and sitting out side for nearly 3 years have not helped, with them scratched, rough and matt.

As I needed to remove some sponsorship stickers from them, this made them look even worse, as they took the paint off as they came off! I’d got the paint already (Signal Green, a ‘standard’ RAL colour, so it’s cheap and easily matched), so I cleaned them up and rubbed them down with fine paper to try to get the primer to stick. The primer is an old can (from when I built the car in 2007), and when I opened it up, it looked hideous. Stirring helped, but it had lots of lumps in, which isn’t good for spraying, so I filtered this out with a high-tech arrangement using an old sock! Looking at the thinners I thought I’d need to give up when I saw this:

But I thought I’d ignore it and have a bash anyway. Primering went pretty well, spraying them off the car in the back garden as it was a nice day, and then I put the green on; it took a bit of experimentation with the mix to get it to spray well, but in the end I got it right and overall they look much better than they did before – not bad for a £25 paint job.

The pictures don’t show just how much better they look, and now they are back on the car (having welded replacement bolts for those that sheared off), it looks a lot better.

Now I just need an engine and gearbox in it!

HALT!

by Darren on Sep.23, 2011, under Build

There are many things that can go wrong with cars; they are complex devices with thousands of parts, and so everything doesn’t always go to plan. I am largely used to that. But I am, at present, not a happy bunny. I have tried to get everything sorted out for this weekend so I could build the new bottom end and get the engine in one piece, and also sort the diff out; in an ideal world this weekend I would even have got the engine back in the car, if not running.

But none of that is going to happen. Despite having originally asked for a quote on the engine parts over 3 weeks ago, and ordering them as soon as I got a reply, I do not have any of the parts I need for the bottom end, and the supplier hasn’t exactly been helpful in addressing the issue, simply saying “they’ve been sent”, and it can take “3-7 working days”. Given that it’s now been 9 working days, I’m not pleased. In addition the diff plates I ordered on Wednesday which I was told would be sent that day have also not arrived. Not impressed given that I’ve paid £9 for delivery on what is probably 300g in weight to deliver.

So this weekend there will not be much progress, and it’s pushed me back at least a week, more if the weather is bad next weekend; typically this weekend it will be good. I have a few jobs I can get on with on the car, such as painting the bumpers and sorting a few niggles out, but mostly it seems this weekend will be wasted as far as getting the car done is concerned. Did I mention that I’m not happy? Anyway, here’s my attempt at an arty shot, with the Skoda asleep in the drive at night.

Gearbox time!

by Darren on Sep.18, 2011, under Build

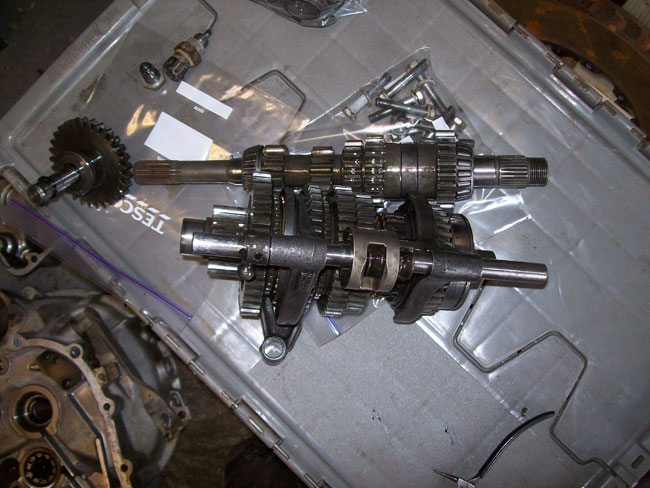

So, at the moment I have a bit of an enforced delay – I’m waiting for the pistons, liners and bearings to rebuild the bottom end of the engine. But one thing that I’ve never quite been happy with since I bought it is the Limited Slip Diff (LSD) that I have. Long-term readers may remember the DNF on Rallye Sunseeker 09 when the old LSD I had (which I never found the maker of) exploded on Stage 4, leading to a broken gearbox, an unhappy crew and a big bill. But the replacement Gripper diff has never really locked up in the same way that the previous one did, and as I have everything out, I thought it was time to investigate, so I stripped the gearbox to get access to it.

Again, long-term readers will remember that this is one of my least-favourite jobs on the car – splitting the gearbox is something I’ve never found too easy (and indeed I learned how to do it the hard way originally, making a right mess of the first box I attempted to dismantle). But with practice and a bit of thought then it becomes easier, and indeed when I got my Mum to hold a circlip open while I tried to move the casing it made it much easier – it was about 20 minutes to get the whole thing apart and the diff out.

Fortunately everything inside the box looks in good condition, and the problem on the Sunseeker with the oil leak (due to three bolts coming out as I’d not replaced the lower mount properly) had no effect on anything that I can see – all the bearings and gears look as they should do. An LSD is necessary in a performance car (yes, the Skoda!) to allow more grip and traction – the problem with a standard diff is that if one wheel has no grip (such as on mud, or in the air) then all the engine’s power will go to that wheel; I’m sure some of you have experienced this in a front wheel drive car when you try to turn and accelerate at the same time and the inner wheel just spins. The LSD stops this, but how much it does it by is part of its setup, and one thing you can measure is the pre-load on the diff, which is how much torque it takes to turn it. And the Gripper was set to 5ft/lb, which is WAY less than it should be, I believe (although I’m asking about as I’m not 100% sure) – I’ve read it should be more like 30-40 for my application.

So I set about taking the diff apart to see what was going on inside. I didn’t find anything of note, so I think this may be somewhat beyond me; if it was the kind of part you could take off and put on easily then I’d be willing to experiment, but it’s not for me, so I will be taking advice and possibly sending the diff off to get it set up correctly.

Other than that, no news really; I’m hoping to get the engine parts before next weekend, and get the engine built next weekend; I’d think the whole lot will be going back in the car the weekend after, which is largely on schedule. I’ll also be ordering the replacement drivers’ seat this week as well, which is the last significant expense (hopefully!) to get the car ready. Hopefully.

Better get cracking!

by Darren on Sep.15, 2011, under Build

I was reminded the other day (thanks Jon!) that it’s only 60 days to Rally GB. Or rather it was at the time. So I thought it was time to get my finger out and get the car ready, so I’ve set about sorting the list of things to do out. Fortunately the weather has been good today, and even more fortunately, I got the afternoon off completely out of the blue. So I thought it was time to get the engine and gearbox out, so I can get ready for the new bottom end to be mated to the head, and then put back in the car. Obviously I’ve done this a fair few times now and most of it has been on and off regularly, so I hoped that nothing would go wrong, and that was pretty much it. At 2:30 I drove the car into place, and by 4:45 this had happened:

I’d have done it in under 2 hours but I had a visitor for a while – it’s just like the Haynes manual, really – 1: Undo Bolts. 2: Remove Engine. I’m not going any further with stripping the engine down as it currently runs, and while I’ve had some of the engine parts turn up (OK, 2 gaskets!), I’ve not had any of the others (bearings, pistons, liners, shims, etc) – they are coming direct from the Czech republic courtesy of Jorily, so I’m hoping they’ll arrive during next week and I can get the engine built and refitted by the end of next weekend.

In the meantime, the rear shock has been sent off to Proflex to be repaired, I’ve bought and received a new Terratrip probe and the new straps to make the extinguisher legal (it will be sent off for service on Monday), so that should only leave the seat to buy, which will have to wait until I get paid at the end of the month – this self employed lark is all very well, but it makes it difficult over the summer! I also need to take a look at the diff as it’s not really got much preload on it so I want to beef it up a bit – nothing crazy, but it can do more than it currently is, for sure. I should get a chance to split the gearbox over the weekend and measure the current preload and then see what needs to be done – Gripper diffs have fairly cheap parts so even if it does need plates it won’t break the bank, thankfully.

Tonight I’ll be putting some areas on the car on eBay, so check out the Sponsorship page above if you’re interested and want to bag yourself somewhere on the car – the first space is already gone!