Build

Anything else care to go wrong?

by Darren on Oct.14, 2007, under Build

OK, no ‘progress’ report last week, and for the simple reason that I had ‘a bit of an accident’ so I couldn’t type. Actually I couldn’t do a lot last Sunday.

But there has been progress of a sort. When you’re under the cosh and not getting the job you’re doing done, what’s the best thing to do?

That’s right, kids, take on another one!

Yes, I’ve bought another car. Now this might sound like the plan of an idiot, but there is some logic behind it. I’ve bought a brand new shell with a weld-in cage, a donor car, a group A engine on Weber management, some proflex (in need of a rebuild), sumpguard and 2″ exhaust.

Now, you might think “what has he done this for?”, but it’s fairly simple. The pistons looked not to be arriving, and that would have meant I’d have been back to running a standard engine, which would have sucked. So, the idea is to build R477 KRU using the engine I’ve just bought (but running a standard inlet manifold to be Group A legal), and use this for Rally GB, and probably the Sunseeker ’08 too. After that, build the other car, and sell one or the other to recoup the investment. It’s obviously a lot of work, but it was that or do WRGB on a standard engine, and that wouldn’t have been much fun on the hills.

So, I’ve spent a day getting the donor car and then stripping it (240 mile round trip, plus 5 hours from start to finish getting the car down to a bare – and I mean bare) shell, and it being removed. This Tuesday will be another trip, this time to pick up the brand new shell (by putting the suspension from the donor car on to keep it rolling), and then putting the doors/screen/etc into the new shell so it’s a rolling shell and not too much of a mare.

But back to the build – some progress has been made – front and rear suspension is now on, the handbrake works, the tankguard is made and fitted, the cutoff plate is made (just need some screws and it can be fitted), and the pulls for the extinguisher are fitted. Radiator and headlights are back in, and most of the loom is now re-plugged. I’m told my gearbox will be here this week, but then I’ve heard that for the last two. Fortunately I have next week off, so I should be able to get it all together, running, MOTd and maybe even logbooked. If not, I’m screwed, ‘cos we’re confirmed as running on WRGB.

Today I’ve also painted the front and rear bumpers, something that I was quoted ?160 for doing. And I managed it using about ?5 worth of paint, and in about 45 minutes, in my garden. Yes, really.

Oh, the title of this refers to the fact that up until about midday today, this week has been a complete disaster. I’ve got lots of work-related trouble (none of it my own doing), and everything just seems to be going wrong.

Any offers of help, money or sympathy will be received with pleasure at djaychela (at) hotmail (dot) com.

Another day…

by Darren on Oct.02, 2007, under Build

… another minimal tale of progress.

Today’s task list was wiring and dashboard. The wiring mods are fairly straightforward for the most part – provide a switched feed from the main beam for the relays that will power the pod, provide a switched, permanent and light-fed power supply to the roof (for the navigator’s lighting), wire in the cut-off switch (which means breaking into the standard loom in a number of places) and also tidy the standard loom up whcih looks like an old mummy after a few years, cloth tape which rips really easily, plus provide connections for the navigator’s horn and washer buttons. Just re-taping it took a while, and the rest of the mods took a long time, most of the day. And then there was fitting the dashboard, which predictably took more cuts than I’d expected (I’d done it before, but only in two parts, when they were screwed together it took more to make it fi), and then modding the glovebox lid to open past the rollcage (amazing what you can do with an angle grinder and plastic). And that, for the most part, was the day done. I know I worked all day, but it seems that nothing got done really.

In addition, I’m STILL waiting for the pistons to turn up, and tomorrow is supposedly the day that the gearbox gets finished. I just have no idea how it’ll all get done in time – at this rate it won’t be ready for WRGB 2008!

Slow going….

by Darren on Sep.30, 2007, under Build

…. So I’ve eschewed such things as a social life, and spent the entire weekend working on the car – started at 8am yesterday (til about 8, on and off), and all day today too, pretty much. However, what’s been done has been frustrating – it’s taken what seems an age to achieve not very much. All four doors are “complete” – i.e. the windows how have the window film on, they’ve had all the overspray removed, electric window mechanisms are now fitted (don’t moan, kids – with the cage in, you can’t use the front winders at all, so I thought I’d do that instead. I know this means you couldn’t open the windows with the cut-off pulled, but then you wouldn’t be able to open them anyway….), and so on. Plus I’ve fitted the fuel pipe as much as possible (I didn’t have the right size cutter for the front bulkhead), and de-taped the wiring loom for the main feed to be connected to the cut-off switch), plus getting the cable for the cut-off (welding cable, 35mm stuff) and cutting it to suit (although crimping the terminals on will be an achievement in itself). The rear lights and loom are re-fitted, and the loom has been cleaned up and put back where it should be. I did want to get the wiring mods completely done and the fuel tank back in, but I’ve got Tuesday off, so maybe then….

Anyway, here’s what it looks like today….

Slowly….

by Darren on Sep.22, 2007, under Build

…. progress is being made.

On Tuesday, something monumental happened – Paul phoned up, came over, and sprayed the car! He’d never even used a spraycan before, so it was a learning experience for him, and painting the inside of a car with a cage in isn’t easy. But he soldiered on….

… and finished the primering, and then we went off to pick up the new sumpguard – designed by me. I say “designed”, I mean drawn on a bit of paper and handed to someone to make. One week and £250 later, I have a 6mm sumpguard, with reinforcing strips and angles.

The downside of owning a new sumpguard is that you don’t want to scratch it – when we tried it under the car we were really careful with it. No need really, is there?

Paul then proceeded to put a coat of white on, although it was very hard work – definitely not a job I’d take on again, EVAR!

Today the weather has been poor – early (7am), Kev was going to come over to paint, but it was all foggy which wouldn’t have been any good at all, but around 3pm it cleared up, but Kev’s at a wedding today, so I soldiered on and put another coat of white on. And now it looks like this:

The engine bay is all painted (although there will need to be more work once the sumpguard mounts are done), and so is the rest of the cage.

Unfortunately it’s not a great paintjob, but hey ho, etc. It’ll do. The old car was a right mess inside, and next summer I can strip it out and do it really well. Or something!

In other news, the brakes are re-conned (calipers re-worked and painted), and after one more coat (and some touching up) the interior of the car can be done, with the wiring being the next job – all the bits to do it properly have arrived. Splendid.

Oh dear…

by Darren on Sep.15, 2007, under Build

Sunday saw two momentous things happen.

Firstly, I finished welding the roll cage up – a truly great moment

Secondly, I did my back in again. Just grinding off a pointless bracket to get the car ready for paint, and I’ve been really done in since then. I write this on Saturday and I’m still unable to bend properly, I have to ice it every 2 hours, and it’s generally poor. Driving is painful and work isn’t on the agenda. Which is a total nightmare – it’s looking almost impossible to get the car done before WRGB entries close, and that’s the only way I’d enter – it has to be logbooked and largely complete for that. I have a week off (half term) in October, but I don’t think that will be enough.

The only upside is that I mentioned on the phone to a friend (Kev, who used to navigate “back in the day” with me) about painting the car. One of those moments where you say something as a joke and hope they’ll say yes. And he did!

So, although I’m unable to do much at all at the moment (and certainly won’t be for at least a week, if not two), the car has progressed – it’s now primered inside.

Kevin James Jackson. Legend.

Is anything simple?

by Darren on Sep.07, 2007, under Build

Changing handbrake cables is usually a pig of a job, ‘cos it involves removing both sets of rear shoes to do it. Handily, this wasn’t the case with the Felicia – it’s possible to unhook the cable by moving the lever inside the hub forwards, and there’s enough spare (due to having separate cables) to get the new ones in. It was looking like a good evening….

… and then I changed the wheel bearings. Left side one – piece of cake again, a near-perfect job. Looked and worked perfectly. And then I did the right-hand side one, and for no apparent reason it binds when adjusted up. I’ve checked everything I can think of (and this was quite a lot) and it won’t adjust up properly. I think it must be a defective bearing, so I’ve ordered another one and will have to wait until Monday for that.

On the upside, I’ve bought a spray gun and ordered all the paint to do the car inside, engine bay and the bumpers as well. Hopefully next Sunday it might look a bit more like a rally car and less like some abandoned project. Tomorrow I’ll finish off the welding and start prepping the interior for paint.

Oh, and the pistons still haven’t turned up.

And Chris Bennett still owes me a gearbox, diff and ?800.

.. and a little more!

by Darren on Sep.03, 2007, under Build

So, it’s been back to work today, which obviously hampers the build somewhat. Regs for WRGB were supposed to be coming out on the 26th, but they’ve altered it back to the 5th again, so I think I’ll have to wait a couple of weeks (at least until the shell is painted and rolling with the rally suspension and brakes on) before entering.

But this evening I’ve finished off the rest of the welding on the floor and started doing the strut brace mounts… when the welder broke! Well, it mis-fed the wire inside itself, and it was pure luck it didn’t touch anything live and blow up! It’s fixed now, but it was getting cold and I had a few twinges so discretion said call it a night! I’ve got a large shopping list to buy tomorrow so I’ll crack on with all of that, plus hopefully get the strut brace mounts done, and get the car back on its wheels.

Will it be ready in time? And will I bet ?1500 on the outcome of that question? Wait and see!

…. and he’s back (pun intended)

by Darren on Sep.01, 2007, under Build

Well, for once there’s good news. It’s good news that is still bad, but there you go. The back issue hasn’t taken anywhere near as long as usual to improve – normally i’ll be done for a couple of weeks, but only 5 days later I’ve got back to welding the car, and finished off what I was doing, which was filling in the holes in the floor. Reason for this was that at WRGB last year, where we dented the floor, the plugs came out, and then the inside of the car was muddy as hell, which was a nightmare, and even got the WRC tracker of doom covered in mud, which is never a good thing.

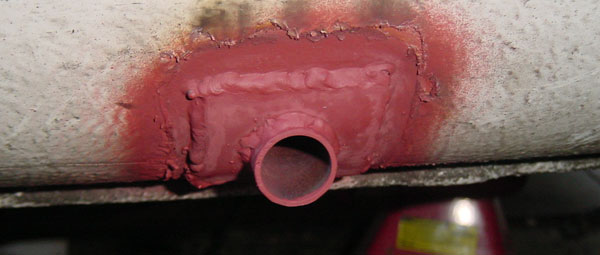

So I’ve taken precautions this time, and welded up all the holes in the floor:

Not a huge amount of progress (still some cage welding to finish off, and the final tube to place), but it’s my birthday tomorrow so I’m going out tonight. I’d like to think that I’ll do something on the car tomorrow, but I doubt it. One thing’s for sure though, it won’t be up and running for the entry date. Damn.

Pete Tong, second set

by Darren on Aug.27, 2007, under Build

Back – done. Car – not done. Arse.

Well, nearly.

by Darren on Aug.25, 2007, under Build

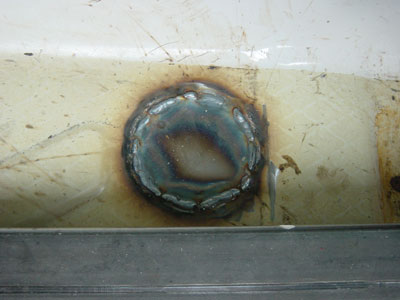

So I’d planned to get the cage finished today. Mice and Men, etc. Reason being that firstly I didn’t get started until later than I planned, but mostly because there was a LOT of awkward welding to do on these tubes meaning muchola contortion, a lot of electrode re-grinding (if you touch the electrode in the weld pool you need to do this, and each time I need to wait for it to cool down before doing that), and also a bit of “I’m bored” also. Which meant that I started something else this afternoon instead – an “extra” (as if I have time), sill stand holes. This might seem OTT, but fitting these will mean I’ll be able to get a quick-lift jack for the car (and the jacking time is the biggest time-waster when changing a wheel) and not have a knackered underside as well. However, fitting them can be a bit of a hit-and-miss affair, reason being that you need to drill a large hole through the sill, which is 4 pieces of metal across around 150mm. I don’t have a drill big enough for this, or a hole-saw deep enough, so it needs to be accurately measured and then done from the inside and the outside. At the back this means being under the car, which isn’t too bad without the tank and exhaust there. And amazingly, I’ve done 3 and got them all within a mm of where they should be, which is good enough if you ask me. This might not look very pretty:

But it will do when it’s properly painted, and it’ll make a world of difference to working on the car.

So the cage is nearly done – a few little bits to weld, and one more tube to place which is a piece of cake – just runs between the two strut towers at the rear. Shouldn’t take more than a couple of hours and it’ll be done. Pity the weather hasn’t been this good for weeks, I reckon I’d have a finished car stood there by now if it had! But here’s how it all stands…

Tomorrow, etc….