Author Archive

Two steps forward…

by Darren on Nov.02, 2010, under Build

… and I’m not sure about the rest!

But a quick update anyway…

HANS Device: After being let down in the loan department (odd as I was offered the loan rather than asking for it), I’ve hired one from Evo Rally Parts. One less thing to worry about.

Helmet: Well, it looks like the person I bought the helmet from for Paul has at best been slack, and at worst has ripped me off. Odd given that he advertises a lot, has a company as well as his Motorsport shop – Paypal claim has been initiated, but it’s left me £233 out of pocket, and more to the point, without a HANS-equipped helmet for Paul. So it looks like I will have to buy a new one, which is a) expensive and b) not ideal. Grr!

Tyres: These should be with me tomorrow – providing the seller hasn’t been ‘economical with the truth’ I should have enough tyres for the event, just got to get them swapped over which is easy enough.

Stickers: The final ones should hopefully be with me by the weekend – if not then I’ll have to give a number of people some money back!

Other than that, there are just a few little bits and pieces to do – the “To do” list is pretty short, with only one job actually being more complex than a simple bolt/screw/clip on (which is just a small alteration to the mapping, should be easy enough to do in about half an hour).

And that’s good news because on Saturday… I shall mostly be navigating on the Tempest rally, with Tony in the 205! Nothing like a busy week’s rallying!

Sponsortastic

by Darren on Oct.30, 2010, under Build, WRGB 10

Day off? As if! Still things to do, but I’ve made it a nice light one – partly because I really do need a day off, and partly because the weather is alternating between rain and shine. So, a bit of cleaning off (after Burley came over and sat in the car just to check he’s OK), read the 7-page Health And Safety Instructions for the service park (make of that what you will, never seen anything like that before), and put some stickers on the car!

So, if you want to join these people, you have until Sunday night to BID ON EBAY!

D Day.

by Darren on Oct.29, 2010, under Build

Today was the day I’d booked the car in for a run on the dyno at Veysport – Andy who was at Triton (who mapped the car in 2008) now has his own business in Verwood, so I booked time at 3pm. In the morning, I did a few things on the car including changing the brake fluid and bleeding them, and then started up and went for a drive. And yet again, problems. The car was running as rich as hell – about 10:1, instead of the ideal 13.5:1. I limped back home, and started checking, and found that I’d made a mistake before – the standard fuel pressure regulator actually ran at about 3.75 bar, not the 3bar I’d seen at rest. This explained the “rich as hell everywhere” I was experiencing. But didn’t change the fact that I had a car which needed to be finally mapped at 3pm, only 4.5 hours in the future. A quick bit of research and it looked as if a 10% cut in fuel would return things to normal, so I put this into the map, and the car still wouldn’t start – I’d spent too much time turning it over before realising that the ECU connector (whose design I have always hated, Mr DTA!) was half off, explaining the total lack of firing, and now the battery was flat. G-reat. Put it on charge, walked away for a bit.

Half an hour later I put another battery on via jump leads as well, and gave it a go. 10% was clearly too lean, the car started, but spluttered a lot, so I re-set it to 5%, and the mix looked a lot better. Went to drive down the road, but it was spluttering and backfiring in the exhaust. Really odd, given that the mix looked spot on from the O2 meter, so I persevered with it, and it cleaned up after a mile or two – it seemed that the plugs had got fouled and needed a bit of time to clear. By 5 miles it was running sweetly, even ticking over. I then realised that the brakes were much better after someone did a stupid move in a traffic queue right in front of me!

But would it last? A couple of starts later on seemed to indicate that it would – so hopefully this is a case of oversight rather than an odd problem rearing its head again. Tammie came over (originally we’d planned to go out), but given the lack of time we settled for Pasta, as I had to go to work before going to Veysport. This gave me the opportunity to let the car cool down again (it restarted fine after 90 minutes), and also drive a bit on dual carriageway and do some overtaking on the way there – it seemed to be going OK, and unlike the last engine seems quite willing in top gear to overtake.

Once I got to Veysport we hatched a plan – last time showed that a lack of cooling on the dyno wasn’t great for the engine (and particularly the oil pressure) so we decided to do a power run, check the fuelling with a run or two more, and then see if there was anything to come from advancing the timing. However, given what happened the first time on the dyno (with a dodgy engine, but you still feel nervous) I was not particularly calm at this point; a disaster now would mean game over, realistically. Andy got the car on the rollers, had a good look about, and then did a power run.

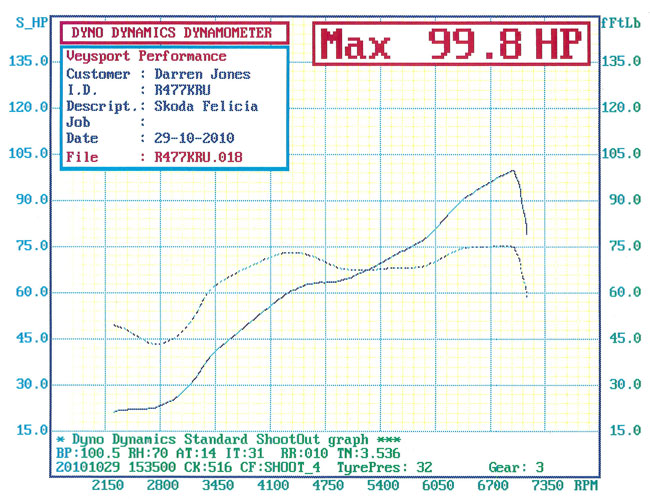

I was pleased to see bigger numbers than last time, already. The fuelling was a bit off (slightly lean), so we put more in and did another run, getting slightly more power and ironing out a bit of a flat spot, but with a spot on mixture throughout – so my preliminary work with the LM-1 had really paid off (not only in terms of money but more importantly giving the engine an easier time). So it was time to adjust the ignition timing; I didn’t realise just how critical it was; Andy explained that half a degree can make or break the power an engine makes (perhaps seeing an extra 5 bhp), so we dialled in extra advance and did another run; there was no difference at all in the power, so clearly things were set correctly already (no detonation, but there’s no benefit in having more advance than you need), so we dropped it back and did a final run. The end result:

Not quite the 100bhp I’d wanted, but damn near it. The shape of the curve is interesting – the drop at the end is the rev limiter cutting in; and rightly so – 7000rpm is the safe limit for the engine components I have, but there’s clearly a LOT more to come if the engine could rev higher, as you can see from the line the curve is following at that point – the head and manifold clearly can flow a LOT more gas than the previous engine; unfortunately steel rods and forged pistons would massively increase the budget, and also steel rods wouldn’t be legal in Group A, alas. But the engine feels good to drive, and is making more power than the previous engine did at peak for over 1000rpm, which is good. I’m sure there are people reading this who think that 100bhp is a joke, and maybe it is, but it’s going to be a big improvement on the stages; I’d love to have 130bhp or so, but it’s going to be good enough (hopefully) to go quicker than before.

So, with that done, it was… done!

The drive home was thankfully uneventful – there are a couple of flat spots I need to address (which are best done on the road, as they’re dynamic things), which I can do tomorrow or on Sunday. I need a break, but it finally looks as if nearly everything is done. Nearly. Still to do:

- HANS device – I’m still waiting to hear back about the one I am borrowing for Paul

- Helmet for Paul – despite paying for it over 2 weeks ago, it’s still not arrived. Yes, I’ve chased the seller.

- Tyres – these look to have been sorted, I just need to arrange collection for them, but they should do the trick.

- Stickers – these should be coming tomorrow – the eagle eyed will notice I’ve taken the “Sponsor this car…” off, as it’s too late now (aside from a late eBay auction frenzy, with 4 spaces up for grabs on the car)

I think that’s it. And I know I need a day off!

…slow going.

by Darren on Oct.28, 2010, under Build

This week I’ve been off work, and for some crazy reason I actually thought I’d got my act together and wouldn’t have much to do. Given the mad panic that I had getting the car ready (ish) for 2007, and even looking back at what I’d done in 2008, I was thinking I was well ahead. However, my list of jobs missed out a couple of things: Firstly that I’d really knackered my left hand up in terms of being useful for work (by the cut I did when doing the trailer), and secondly that one of the jobs was my least favourite, seat mountings; Paul had sat in the new seat, and it was clearly not in the right place, so this meant re-doing all the seat mountings. My least favourite fabrication job, because it’s awkward and tight in the Felicia (it would be quite easy in a larger car), and also because it’s quite difficult as a result of this to get everything in place, meaning that the seat needs to be in and out of the car several times (10, I think!), to make sure each mounting is right – it’s easy to assume that you’ve got it all right and then find out you can’t get the seat in (I did this in the Favorit!). However, that wasn’t the case here, but it still took all of Wednesday and some of Thursday morning to get it done. It’s now as low as possible in the car, and as far back as possible too – when I get in, it feels like being a “real” navigator as you can’t see the end of the bonnet. This pleases me, and I celebrated by repainting the floor (as it looked horrendous). Hopefully Burley’s frame will fit in too.

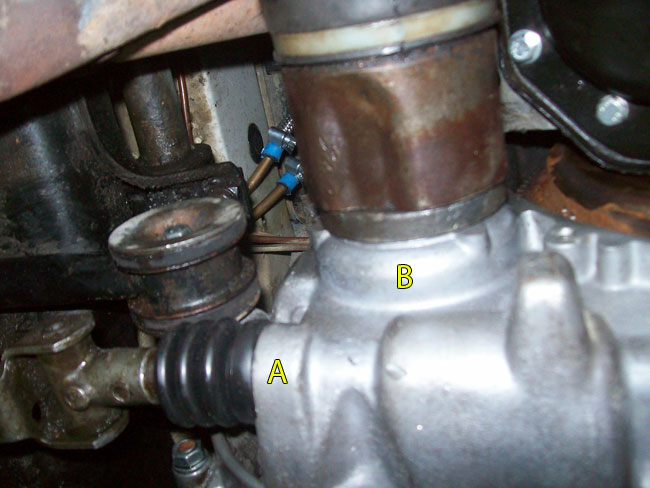

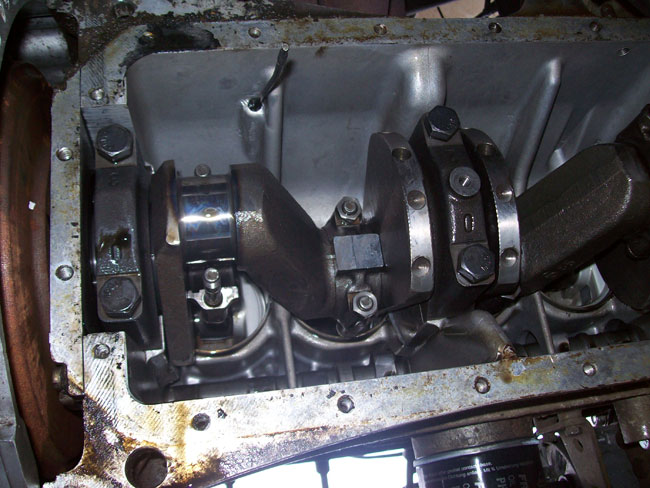

So, a day and a half down to a single line on the list of things to do. But this left only a few mechanical things, first of which was sorting out the leak in the left front strut. This isn’t a “service” item, it’s a user-item; when you put the leg together (with the spring) it needs to have a small amount of oil put inside the strut leg, which is then sealed in place with the bottom nut and a copper washer; last time it hadn’t sealed properly, leaving a pool of oil on the floor. Replacing it meant taking the strut off (which involves a few other steps), and then sorting out the leak, which was done once it was all cleaned up and bolted up properly. And next was another leak, or rather a pair of them – the right-hand driveshaft seal on the gearbox was leaking (which I didn’t think would be too difficult to do), and the gearshift shaft seal (which I did) – they are B and A respectively on the picture below.

At this point, Peter turned up, from Top Oils, who are my biggest sponsor! He had brought down the oil for the engine and gearbox, which is made by Bardahl and provides excellent protection for the components of engine and gearbox – they contain Fullerene, carbon ‘balls’ which have impressive mechanical properties, and should help protect the Skoda’s engine which regular readers will know gives the centre bearing a hard time. We chatted a while about the event and so on, but then it was lunchtime and then back to work. I decided to attempt the gear shift seal first, and was really surprised that it came out very easily (Thanks Jim for the tip!) – as it had a lip on it outside the gearbox it was straightforward and my nightmares of breaking the seal and not being able to get it out were unfounded – 5 minutes later after draining the oil, it was changed. To do the shaft seal, the shaft needed to come out, which was fairly straightforward, and then levering the seal out and tapping a new one in; getting the shaft back in without damaging it was done, albeit twice as the gripper diff’s lack of a chamfer always makes fitting the shafts a bit of a lottery, even with my ‘grease the circlip to keep it in the centre’ trick.

Then a few bits an pieces, tightening things, replacing missing fasteners and so on, and then some items arrived; I have spent some of the sponsorship money I got on new equipment, in this case a pair of Fluorescent “Task Lights”, which are low-energy (38W), but give out LOADS of light – a great bit of advice from British Rally Forum, especially at £35 for two, delivered. They are low power enough to be runnable from an inverter from a car or van, but of course I want to run them off my generator, so I got that up and running, and worked a treat.

Time for an engine and gearbox oil change, with the new Bardahl oil being put into the engine…

… and gearbox…

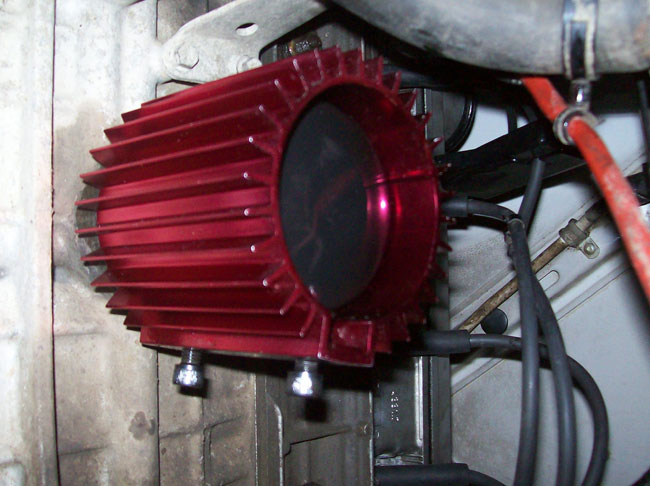

Ran it up, plenty of pressure, which is good, and a nice quiet gearbox too. Lovely. Another thing which may help a bit is a total bit of boy racerism, but was a cheap (£7) and easy fit – an oil filter cooler – essentially a slip-on heat sink for the filter:

Hopefully this will help keep the oil a bit cooler, and it certainly won’t hurt; while there is provision in the regs for me to add an oil cooler, it’s difficult to find somewhere for the cooler radiator to go that is both cool and not vulnerable, and obviously damage to it would mean no oil and game over – this isn’t anywhere near as efficient, but has no reliability issues. Image issues, yes!

Next it was time to change the front brake discs – they weren’t too warn, but they were rusty, so time for a new pair, by which time it was getting dark and the work lights were really useful:

And that was about it – not a lot I could do as next job was to bleed the brakes (to change the fluid really), and I didn’t have any fluid, so that was it… As it stands, the car is nearly ready. Tomorrow is time for mapping on the ignition, so hopefully it will go better than previous visits; I’m rather worried about it!

Hopefully all will be well…. see you tomorrow!

Other things…

by Darren on Oct.24, 2010, under Build

For once, the car is mostly done, a couple of weeks ahead of when it needs to be. The list of jobs to do is fairly short, mostly chasing a small oil leak on the gearbox (which I think should be fairly easy to sort out, being 2 oil seals), re-filling the lubrication on the front left strut (when you assemble the proflex legs they need 80cc of oil in them, and the left one leaked because the sealing washer, er, didn’t!).

Yesterday Paul came over, and we checked a few things on the car, which all seemed OK. There were a couple of things that need doing, but nothing major and no surprises. However, I started the car up then and it didn’t seem too happy. I did the same again today, and it was also rough. And lo and behold, the same problem had resurfaced – a lack of fuel pressure. I thought it may be the pump, but replacing that would be an awkward job, so I tried changing the pressure regulator instead, by replacing the fuel rail (which I’d removed the regulator from and used a remote one) with a standard one. It took a bit of time to do as it’s awkward, but it led to a rock-steady 3 bar fuel pressure, and once the plugs had been cleaned it ran spot on again. Hopefully that’s the back of that problem, and the car will run properly – certainly I felt rather differently about it playing up knowing that in 3 weeks time it’ll be in the Welsh forests (all things having gone to plan).

But to get to those forests, I need a trailer, and again hiring one for the week is something I don’t have money for. So it was time to fix the problems with my trailer – the plastic mudguards had been broken since I bought it and patched up here and there, so I bought some new ones. In addition the “tailgate” was rusty and rubbish, so that needed to be replaced. While these sound like simple things, it was pretty much a day’s work to get all that sorted, although it now works a lot better than before. But there was a problem – while cleaning the tailgate up ready for painting, a sharp edge caught my left hand and cut a 3″ long gash in it at the base of my thumb – the kind of thing you do where you know it’ll be messy and you don’t want to look at it! It bled a lot, and put paid to doing anything much for the rest of the afternoon. Not ideal as I need to be doing stuff, so I’m taking it easy again! Tomorrow should see the wiring finished on the trailer, and then some work on the car, hopefully getting everything finished off.. well, by Tuesday anyway.

…and we’re in!

by Darren on Oct.21, 2010, under Build

Just a quick update for a few things:

Firstly, I’ve had confirmation that our entry has been accepted into Rally GB. So we’re in!

Secondly, the car has taken on the first sponsor’s sticker; the rest should be coming next week, so some pictures will follow next week (when everything should be finished, really)

Thirdly, pretty much everything is in place – cottage hired for the week, service crew, van, etc. There are a few things to get sorted – waiting for Paul’s HANS and also the new helmet I’ve bought for him (yes, really!), and also tyres – I was really hoping to get some discount from Kumho in return for space on the car, but alas it looks like I’ll have to pay full price for the tyres, which is not cheap, and I’m basically out of money! Oh dear!

Finally, it is looking like we will have a form of “satellite tracking” during the event for you to see where we are at any point; I’m spending this evening and some time this weekend trying to get the site working better on mobile browsers (with a theme which suits small screens better), and in addition adding a page which will show our latest tweet and map position, so you can follow us easily during the event, and I’m hoping it’ll be possible to tweet at the beginning and end of each stage. I’m navigating on the Tempest the weekend before Rally GB with Tony, so I should be able to give that a dry run as well. Anyway, plans and so on. I have next week off, so there should be lots of progress. Hopefully!

Getting closer

by Darren on Oct.17, 2010, under Build

Well, one thing is definitely getting closer – Rally GB 2010. It’s only four weeks today that the last stages will be running. So really it’s three weeks to go. Usually at this point, things are getting desperate, so I’ve had a nice week thinking that although there are still things to do, a lot has been done and the car is mostly there – running well, etc.

I have a list of jobs to do, and it’s split into three sections – mechanical/electrical things (i.e. bits that make the car go), mandatory (things which are related to safety and regulations changes), and cosmetic (which are nice, but let’s face it, I could live without). This list gets printed out at the beginning of any time I spend in the garage, and then I’ll do something from it. This weekend’s main thing was improving the engine mapping, so on Saturday morning I got out in the drive fairly early (although it was a bit cold) and fired the car up. It ran, but not well – it seemed really lean, and the O2 meter confirmed that it was running very lean. I expected it to clear once it warmed up, and the quickest way to do this is to drive the car. On the way down the road I thought it might be getting low on fuel, so I limped to the petrol station, but it made no odds. I had a very slow, sick car that was a challenge just to keep it going and get it home – not helped by a couple of idiots cutting me up and blocking me in on the dual carriageway outside my place.

Anyway, got back and had a look – everything on the ECU seemed fine – right speed, right map settings, until I saw that there was no compensation programmed in for air temperature changes. Which is necessary as cold air is more dense, so more fuel is needed. A bit of searching came up with the right figures for this, and I set them up, as well as isolating the temperature sensor from the plate it is mounted on. Should have been an improvement, but made no odds at all, leading me to the conclusion that there was something in the “real world” that was stopping it running.

Last week I fitted the quick-disconnect fuel sampling valve, and it came in very handy for the next test – checking the fuel pressure, which was very easily done by attaching a gauge to the hose that came with the sampling valve, and plugging it in. I was surprised to see that the fuel pressure was 2 Bar (about 30psi), well short of the 3 Bar it should be. A quick tweak saw rock-solid fuel pressure and a car now running properly. I may get a replacement regulator soon, but in the meantime that will do. Then went for a drive and made some improvements to the map – adjusting the rich running on full throttle, which made the car run cleaner, and it will now take full throttle from 1500rpm in top gear (although pulls slowly due to the cam), which is a good thing in case of inept driving (!)

Next up, a small crack had appeared in the exhaust, so that was welded up, and then the next improvement to the car – anyone who saw the pictures of the engine bay after a forest rally will know how messy it can get, and side guards which will stop most of the mud getting in (flung by the front wheels) will improve matters greatly, as well as stop rocks hitting anything important, such as the engine!

This is the right-side one, but the left is pretty much the same. These have been made up from 5mm polypropylene sheet, which is easy enough to cut and bend (using a blowtorch to soften it), but hard enough to resist damage. It also takes rivnuts well, so it made for a nice job, but took a few hours to get right – Saturday was over.

Sunday’s tasks had to be done after fixing my Mum’s car (changing the glow plugs, which is only a small job but took an age as it was so awkward to do), and they were to do some more mapping, and also to chase an oil leak – while it’s not a bad one, there was some leaking from what looked like the sump gasket, so careful cleaning and then running the car was needed to check this, and lo and behold, it was indeed leaking. That’s now been changed for another new one, so hopefully this time it will be oil tight. What isn’t is the gearbox – the gearshift shaft oil seal is leaking, and I can see why – the shaft is quite pitted. I’m not sure whether it’s possible to change it in situ, nor am I sure whether it would make much difference, but obviously what I don’t want to do is ruin it trying to change it and then be unable to do so. One of the driveshaft oil seals is also leaking, so that needs to be done, but that’s straightforward.

Other than that, the list of things to do is now looking pretty small, other than get some new tyres (which have gone up a lot), get a service van hired, and find some money. Oh, and get my licence upgraded – getting a medical done has been a right pain to get done, so I’m hoping that will be done on Wednesday. I have the week after next off, so that’s a big bonus, and although it certainly won’t be like the hell of 2007, there are still lots of things to do.

Like remember (or learn!) how to drive.

Oh, and finally, the cheque has been cashed for Rally GB entry, so I will take it that our entry has been accepted!

Smaller Spaces, part 2

by Darren on Oct.10, 2010, under Sponsorship

As we’re getting nearer to Rally GB 2010 I’ve had a few people ask about smaller spaces, and more details about them, so I’ll put the details here for anyone who’s reading this:

You will get:

A space of 300mm x 50mm on the car

Single-colour (black) text is provided for this price – if you want anything else then you will need to provide it yourself and send it to us for us to apply onto the car.

If you want a larger space, you can buy multiples of the above size – they will, of course, be placed together in the formation you want (either side-by-side or above)

The location of the space on the car is not yet known – it will depend on the number of takers we get for the larger spaces on the sponsorship page, but it will be in a good location on the car, not on the sills or something like that – it’ll be somewhere readable when the car is photographed. If you want a specific area, then please contact us to work something out.

Buying a space is simple – send a PayPal payment of £20 to darren (at) skodarallyblog.fun – obviously this is an email address and you’d replace the (at) with an @ sign – and include a message with your payment with the text you want on the car.

Any questions, please email me or use the contact form on the sponsorship page

More progress.

by Darren on Oct.10, 2010, under Build

This weekend has seen some more progress on getting the car into a rally-ready state. The principal problem I was left with after last weekend was starting the car – it was really difficult to get it to start, and the ECU kept resetting because of low voltage when running the starter motor, meaning it was at best a hit-and-miss affair to get it started, and sometimes the car just wouldn’t start. This, of course, would never do, for obvious reasons – I don’t want to spent £4000 on entering Rally GB to be thwarted with a car that doesn’t start on Friday morning. You might laugh, but this has happened to works teams in the WRC before.

Initially I thought the problem was the battery having seen better days – although it’s not seen a lot of work, it has been left for long periods, but a battery test soon corrected that illusion – it was almost exactly to the spec, which given that it’s nearly 3 years old isn’t bad at all. However, that meant things would be more complex than I’d hoped.

To cut a long story short, it was simple – the earth lead between the engine and the car body was loose, and re-fixing it and cleaning the battery terminals up led to a car which fired up on the button as it should do. This was a good thing, so I celebrated by running around like a madman for a few minutes – I’d been dreading spending the weekend faultfinding earthing problems, not something I’m keen on at the best of times. I’d also discovered an excellent tool in the shape of a wire brush for cleaning battery terminals and leads, a bargain at £1.65.

The wiring loom for the engine needed the plug that goes into the ECU re-waterproofed; I’d removed this when trying to find the cause of the poor starting ages ago, and replacing it was a tricky job involving cutting some 40mm-diameter self-adhesive heatshrink to suit, and then carefully shrinking and glueing it in place. Looks good and waterproof now though.

Wiring gremlins then took over; the mapping that I’ve been doing relies on Innovate Motorsports’ LMA-3 box which plugs into the logging meter that I have, and provides information about the engine speed and throttle position (it also records G-forces as well, but these are just for fun). And there was no throttle readout; it turned out that a stray wire had shorted the supply and blown the fuse, although it was still working as it’s powered from the meter as well. Another hour expired by the time this was located and fixed properly. Then the RPM readout wouldn’t work, and it took a couple of hours to track this down to the lead between the LMA-3 and the meter being slightly dodgy – once all the terminals were spotless it worked properly, but that put paid to Saturday.

Next up, the oil leak. The back of the engine was covered in oil, as was one side of the gearbox. To find the leak, firstly it all needed to be cleaned off, which to do properly takes a while, but once that was done I went for a run up the road and… the back of the engine was covered in oil again. Close examination showed the engine block to be different to the other one, meaning that a different dipstick was needed. Doing that stopped it completely; there is now just a question mark over whether or not the gearchange shaft seal a) leaks and b) can be replaced in situ. I have a new one, but obviously if I knacker the old one up and am unable to get it out then I’ll have made things much worse, so I’ll have to keep an eye on it this week.

It was now getting late on Sunday, and time to drive the car again. It now starts up really easily, just needing some blipping of the throttle until it warms up, and it drives pretty well, although there are still a fair few flat spots in the map to work out. On the upside, the misfire at 5500rpm has finally been eradicated with the new mounting for the crank sensor, so that’s a huge relief. Another relief is that the engine is quite happy pulling to 7000rpm (the redline), and makes good power from about 3000rpm upwards. The map is still off – it’s pretty rich in places, so I’ve logged what’s needed and will be doing so over the coming week to improve it as I go, so hopefully by the end of the week it will be ready for a final mapping session on a proper rolling road to get it set 100%.

Other than that, just some cosmetic work is needed – various things inside the car, and painting the roll cage door bars to clean up all the chips it has acquired, and then the bumpers need a coat of paint. It looks as if we have sorted our accomodation for the week at a reasonable price (i.e. something that I can actually afford) although it does mean a bit of a drive each day to get to the service area, the other option is it cost an extra £200 and be nearer, but I just can’t afford it, to be blunt!

Hopefully next weekend should see the car pretty much ready to go, although I have a week off in a few weeks, so that will obviously provide some breathing room if something (inevitably) doesn’t go to plan!

Blimey.

by Darren on Oct.03, 2010, under Build

There haven’t been any updates on here for a few days, but that’s not to say I’ve not been busy – quite the opposite, in fact.

Firstly, I’ve sold a spare car that I had – I had a complete, brand new shell with roll cage that I bought a long time ago with a load of other bits – I had planned to build that at some point, or to use it as a spare shell should the worst happen to R477 KRU. However, storage space for it was going to become difficult in the future, and I needed the money, so I sold it to a chap called Rob who is re-shelling his ex-challenge Felicia, so I know it’ll live on. And what have I done with the proceeds? I’ve bought a HANS device. This may seem extravagant, but hire costs for Rally GB would be about the same as I will lose on buying it, and it gives me the option of using it on other events, including Monte Carlo, should my pipe dream become reality! And more importantly it gives me a chance to see whether or not wearing it in the car is going to work out – I’ve heard several people say that their seat/harness/position made it really uncomfortable, and that isn’t something that I can afford to find out on the Thursday of Rally GB. I’ve sat in the car with belts on, and it seems OK, I think it’s something you’ll just get used to after a bit.

It’s very light (made from formed carbon fibre, hence the funky appearance under a flash), and sounds like it’s ceramic when something knocks on it. I guess it will be somewhat awkward to get off and into the back of the car at the end of stages, but there you go….

Next up: Seating. The FIA’s rules of seat lifing mean that Paul’s seat is out of date (being 5 years old), and the manufacturer won’t re-certify it. So I have a perfectly good seat which needs to be replaced. After a lot of wailing, gnashing of teeth and shopping about, I found a replacement at Larkspeed for £360 delivered. Which isn’t cheap, but is better than the £450 that others were selling them for. To help recoup some of that cost, the old seat is being sold on eBay, and should get me about half the cost back as they are still useful for other motorsport disciplines and for the fast road crowd. The big upside of getting a straight replacement is that bolting it in was straightforward – undo bolts, remove seat, put new seat in, replace bolts. If only everything was that simple! Another advantage of the new seat is that is has a recess to suit the HANS device (my seat already had this), so that’s an upside….

And yes, only my bank account knows the difference!

You want more? Splendid. I’ve got it.

Easy stuff: Air filter. The last one was a bit crap, so I went mad and have replaced it with a K&N filter of nominally the same size. According to K&N’s calculator it’s actually a bit too big, but that’s no bad thing. And being able to fit something in 3 minutes is a good thing too.

Less easy stuff: The crank trigger mounting has been strengthened further, which seems simple but actually took 4 hours to do, with lots of messing about to make it suit a new (and replaceable) crank trigger instead of the old one. This means I can finally get and carry a spare for this most annoying of devices. However, I’ve not actually had the car running with the new one because of the next problem: The ECU keeps resetting itself when cranking, and I think the battery is to blame; it doesn’t go flat flat, but when cranking the voltage drops enough to reset the ECU, and the end result is a car that doesn’t run. This can hopefully be sorted fairly easily, but it means I currently have a car that doesn’t go.

Far more involved: The engine I’m running at the moment has a bottom end that did Rally GB in 07, and those with long memories (or an obsession) will remember that the oil pressure wasn’t all it could be – there were a couple of times when we’d finish a stage and the pressure would be non-existant at tickover. This probably wasn’t helped by the fact that at one point in its life it had been run without any oil! Worn bearings are a fact of life on the Skoda engine, so it was time to try to address this, something that I did before GB 08 with another engine which behaved similarly. It’s fairly easy to do – drain the oil, unbolt the sump and oil pickup, and there you have the guts of the engine – here’s a pic of what it looks like:

If you’re not sure, this is from under the engine, looking up. The white area at the bottom is the sky, and the wiry thing at the top is the dipstick. No.4 big end is removed. Removing the big ends was first, and when they were out, it was easy to see that they had seen better days!

They should be smooth without any wear, not shiny and stripey like these ones are. The bearings that the crank runs on (main bearings) were much the same, although replacing them is a little more involved as getting the top ones out needs a bit more careful persuasion. All good though, and then a case of bolting it all back together, using a new gasket and sealer as the old one was leaking. This took a couple of hours, as I’d rather do it right than quickly, and also I wanted to avoid doing myself in.

More easy stuff: The door bars look shabby (yes, I know, I’m talking about cosmetic things!), so I’ve touched in the chips in the paint from the harnesses hitting them, and they will be then covered in ‘helicopter tape’ which apparently is near-indestructible, so that could be very useful. Plus the door bar rollcage foam was quite shabby (as I kick it every time I get in), so that’s been replaced too. The car’s 5v supply (for the GPS unit, and to charge Paul’s phone which he uses with Memory Map) was playing up, and that was traced to a faulty connection which has been replaced. Plus (more cosmetics), I’ve finally removed the grey and white overspray from the driver’s door shut, which looked terrible. Again, not terribly important but given that I couldn’t get a new battery this afternoon (without paying Halfrauds which I simply refuse to do), I was limited.

Regulations: There are a few things that are needed on the car, and I’ve done some of them to keep with the regulations: First is to replace the names on the rear door window – in previous years this has only been my name, but now the FIA has finally realised that people are capable of reading two names and understanding that there are two people in the car! So both Jones and Burley are there now, with the appropriate flags.

There’s something less trivial though, in that a fuel sampling point is needed; all cars competing in the event need to have provision for the fuel to the taken for testing. While this isn’t something that I would think is a practical issue for us (after all, the line “Go to the Murco, mate” would get the fuel we’re using sorted), it is something we have to comply with, so I’ve bought a fuel sampling coupling and pipe, so that fuel can be taken for testing if needs be.

Note to the eagle eyed – this is only temporary, in terms of the pipe fittings, they will be finished better during the week!

Oh, and mudflaps. The old ones were perfectly good. Until I ran one of the rear ones over, when reversing into the drive after Rally Day (if you go up a kerb backwards, it gets ripped off!). And the MSA have decided that mudflaps now have to be 4mm thick, so I’ve blown even more money on new mudflaps, which are very white and pretty, and 4mm thick. The rears are fitted, but it was raining nearly all day today, so getting soaked doing that wasn’t really a good idea, so I’ll leave the others for whenever the weather is better.

So, that’s it. At present the car is pretty much there – there’s an oil leak to trace (which I’m hoping the sump gasket already has done), the starting issue (a new battery), final mapping, and some cosmetic issues to address, plus some improvements to the sumpguard to protect the engine bay from mud getting in – basically some polypropylene sheet to fit to it. And hopefully that can all be done next weekend.

Oh, and I was mentioned in Motorsports News, after speaking to Sean at RallyDay and on the phone last week!

Entries for Rally GB close on the 20th, which is two weeks on Wednesday. I guess it’s time to enter?